Your Ultimate 2025 Guide: 5 Critical Faults a Sweep Frequency Response Analyzer Uncovers

agosto 28, 2025

Abstract

A sweep frequency response analyzer (SFRA) provides a powerful and sensitive diagnostic method for assessing the mechanical and electrical integrity of power transformers. This technique functions by generating a low-voltage sinusoidal signal across a wide frequency spectrum and injecting it into one winding, while measuring the response signal at the other end. The resulting frequency response plot serves as a unique “fingerprint” or signature for the transformer’s active part. By comparing a current SFRA measurement against a reference signature taken when the transformer was known to be in good condition, maintenance professionals can detect a variety of internal faults. These include winding deformations, displacements between windings, core-related issues, inter-turn faults, and problems with tap changer contacts. As a non-intrusive and highly repeatable test, SFRA has become an indispensable tool in modern predictive maintenance programs, enabling early fault detection that can prevent catastrophic failures, reduce costly downtime, and enhance overall grid reliability.

Key Takeaways

- Compare new SFRA traces to a baseline fingerprint to identify internal changes.

- Use a sweep frequency response analyzer to diagnose faults after a short-circuit event.

- Interpret low-frequency deviations as potential core or clamping structure issues.

- Analyze mid and high-frequency shifts to detect winding deformation or shorts.

- Ensure consistent test lead connections and grounding for repeatable results.

- Document all test conditions, including temperature and tap changer position.

- Isolate the transformer completely from the system before beginning the test.

Table of Contents

- Understanding the Core Principle: The Transformer’s Unique ‘Fingerprint’

- Fault #1: Winding Deformation and Displacement

- Fault #2: Core-Related Problems

- Fault #3: Inter-Turn and Inter-Winding Short Circuits

- Fault #4: Open Windings and Poor Connections

- Fault #5: Issues with Bushings and Tap Changers

Understanding the Core Principle: The Transformer’s Unique ‘Fingerprint’

To truly appreciate the diagnostic power of a sweep frequency response analyzer, one must first step back and reconsider the nature of the power transformer itself. From the outside, it appears as a static, monolithic piece of equipment. Yet, within its steel tank lies a complex, interconnected electromechanical system. Understanding this internal world is the key to understanding how SFRA works.

What is a Sweep Frequency Response Analyzer?

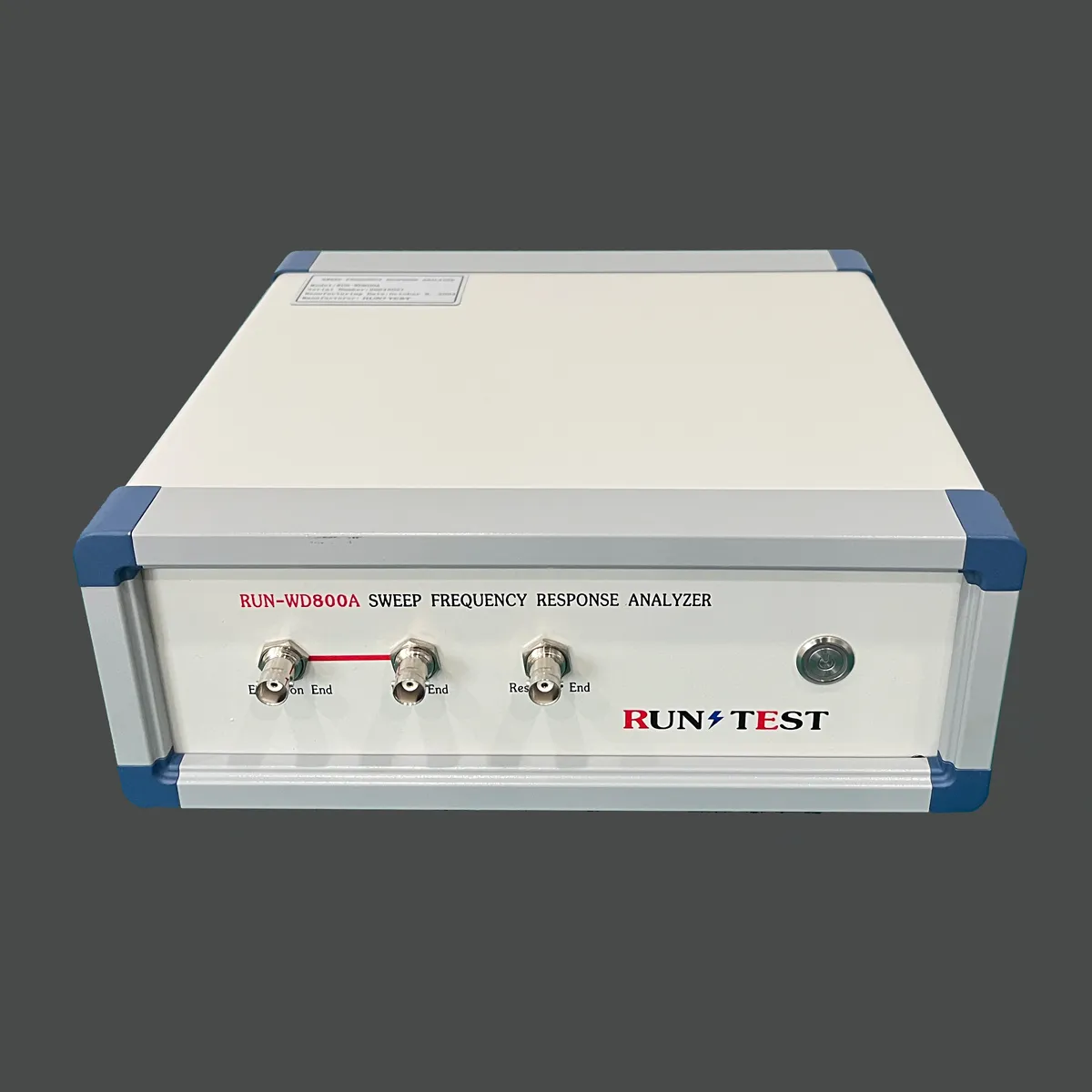

At its heart, a sweep frequency response analyzer, often abbreviated as SFRA, is a diagnostic instrument designed to assess the internal geometry and health of a transformer’s active components—namely the windings, core, and connections. Think of it as a form of electrical sonar or an electrocardiogram (ECG) for a transformer. Instead of sending sound waves or measuring heartbeats, the SFRA instrument sends a series of low-voltage electrical signals at varying frequencies into the transformer and listens for the “echo.”

The process involves applying a sinusoidal voltage, swept across a broad frequency range (typically from 20 Hz up to 2 MHz), to one terminal of a transformer winding. Simultaneously, the instrument measures the voltage signal returning from another terminal. The ratio of the output voltage to the input voltage (Vout/Vin) is calculated at each frequency point. When plotted on a logarithmic scale, this ratio forms a unique graph, a signature that reveals the transformer’s internal condition. Any physical change inside the transformer, no matter how subtle, will alter this signature.

The Transformer as a Complex RLC Circuit

Why does a physical change affect the electrical signature? Because a power transformer is not just a simple magnetic device; it is an intricate network of resistance (R), inductance (L), and capacitance (C).

- Resistance (R): This comes from the copper or aluminum conductors used to make the windings.

- Inductance (L): The primary inductance is generated by the magnetic flux in the core, while leakage inductance arises from flux that does not link both windings. Every coil of wire is an inductor.

- Capacitance (C): Capacitance exists everywhere within the transformer. There is capacitance between each turn of a winding, between different windings, between the windings and the core, and between the windings and the tank.

This complex RLC network has a specific frequency response. At low frequencies, the transformer’s behavior is dominated by the core’s magnetizing inductance. As the frequency increases into the kilohertz range, the interaction between the main inductance and the inter-winding capacitances becomes more prominent. At the highest frequencies (in the megahertz range), the behavior is dictated primarily by the winding’s own self-inductance and the capacitance between its individual turns.

You can imagine the transformer as a complex musical instrument, like a grand piano. Each key (a frequency) produces a specific sound (a response). A healthy, well-tuned piano has a known, expected sound. If a string loosens, a hammer gets misaligned, or the wooden frame cracks (representing a mechanical fault), the sound will change. Some notes might sound flat, others might buzz, and the overall harmony will be disturbed. The sweep frequency response analyzer is the “tuner” that can hear these subtle changes in the transformer’s “music,” allowing an engineer to diagnose the problem without having to open the piano.

How SFRA Testing Works: A Step-by-Step Explanation

The practical application of an SFRA test is a methodical process designed to ensure repeatability and accuracy.

- Preparation and Isolation: Before any test leads are connected, the transformer must be completely de-energized and isolated from the grid. All terminals (both high-voltage and low-voltage) must be disconnected from any external busbars or cables. The transformer tank must be solidly grounded, and the test instrument’s ground should be connected to this same point to create a single, reliable ground reference.

- Test Connections: The SFRA instrument has a source lead (which sends the signal) and a measurement lead (which reads the response). These leads are connected to specific terminals on the transformer bushings depending on the test being performed. There are several standard test configurations, each designed to investigate a different part of the transformer’s internal structure.

- Executing the Sweep: The operator uses the software controlling the specialized transformer testers to initiate the frequency sweep. The instrument then methodically sends signals, starting at a very low frequency and incrementally stepping up to the maximum frequency. At each step, it records the output-to-input voltage ratio in decibels (dB) and the phase shift in degrees.

- Generating the Plot: The collected data points are plotted on two graphs against the frequency axis. The first graph shows the magnitude (in dB), and the second shows the phase angle. This pair of graphs constitutes the SFRA signature or “fingerprint.”

- Analysis and Comparison: The true diagnostic power comes from comparison. The newly acquired trace is overlaid onto a reference trace. This reference could be from the original factory test, a test after installation, or a previous routine maintenance test. Any deviation between the new trace and the reference trace points to a physical change within the transformer.

The Importance of a Baseline Signature

The SFRA test is fundamentally a comparative method. A single SFRA measurement in isolation has limited value. Its meaning is revealed only when compared to a benchmark. This is why obtaining a good baseline signature is paramount.

Ideally, the first SFRA test should be performed at the manufacturer’s facility after the transformer is built. This provides a “birth certificate” of its mechanical condition before it has been subjected to the stresses of transportation and installation. If a factory test is not available, the next best option is to perform a test immediately after the transformer is installed and commissioned, but before it is energized.

This baseline signature captures the transformer in its ideal, undamaged state. Every subsequent test performed during its service life will be compared against this golden reference. Without it, interpretation becomes more challenging, often relying on comparisons between phases of the same transformer or with identical “sister” units. While useful, these methods are less definitive than a direct historical comparison. Documenting every detail of the baseline test—the tap changer position, the oil temperature, the exact test lead configuration—is therefore not just good practice; it is foundational to the entire diagnostic process.

Fault #1: Winding Deformation and Displacement

Of all the potential failures in a power transformer, winding deformation is one of the most insidious. It is a purely mechanical problem born from immense electromagnetic forces, yet it can lead directly to catastrophic electrical failure. It is here that the sweep frequency response analyzer demonstrates its profound capability.

The Silent Threat of Mechanical Stress

Transformer windings are subjected to enormous mechanical forces during their operational life. The most significant of these occur during external short-circuit events. When a fault happens on the power line connected to the transformer, the current flowing through its windings can spike to 10, 20, or even 30 times the normal full-load current.

This massive current interacts with the transformer’s own magnetic field, producing forces of incredible magnitude. These forces act in two primary directions:

- Radial Forces: These forces act outwards on the outer winding and inwards on the inner winding, attempting to stretch the outer winding into a larger circle and crush the inner winding against the core. This is often called “hoop stress.”

- Axial Forces: These forces act to compress the windings along their vertical axis, trying to squeeze them like an accordion. Imbalances in the magnetic field can also create forces that try to lift or tilt the entire winding assembly.

Even if the transformer survives the short circuit without immediate failure, these forces can cause the copper conductors to bend, twist, or shift their position. The insulating paper can be damaged, and the clamping structures that hold the windings in place can be loosened. This is winding deformation. It is a hidden injury that weakens the transformer, making it more vulnerable to failure during subsequent events. Transportation over rough terrain can also cause similar shifting and loosening of internal components.

Axial vs. Radial Deformation: What’s the Difference?

Understanding the two main types of deformation is key to interpreting SFRA results.

- Radial Deformation: This is the bending of windings in the radial direction (inward or outward). Outward buckling of the outer winding or inward deformation of the inner winding changes the distance between the windings, and between the windings and the core. Since capacitance is dependent on the distance between conductive parts, radial deformation directly changes the transformer’s inter-winding and winding-to-ground capacitance.

- Axial Deformation: This involves the movement of conductors along the vertical axis of the winding. This can include “conductor tilting,” where individual strands of copper are forced out of alignment, or “axial collapse,” where a section of the winding is compressed. This type of deformation primarily affects the winding’s self-inductance and the capacitance between different turns of the same winding.

Each type of deformation leaves a different “scar” on the transformer’s frequency response, allowing a skilled analyst to not only detect a problem but also to begin diagnosing its nature.

How SFRA Detects These Shifts

The changes in capacitance and inductance caused by winding deformation are precisely what a sweep frequency response analyzer is designed to detect. The SFRA plot is typically divided into three main frequency regions, each sensitive to different types of faults.

- Low-Frequency Region (20 Hz – 2 kHz): This region is dominated by the core’s magnetic properties. Winding deformation has little effect here, unless the problem is so severe that the entire winding has shifted relative to the core.

- Mid-Frequency Region (2 kHz – 200 kHz): This is the primary region for detecting winding deformation. Changes in the main winding inductances and the inter-winding capacitances cause significant shifts in the SFRA trace. A radial deformation, which alters the space between windings, will cause a noticeable shift in the resonant peaks within this frequency band. An axial deformation, which changes the winding’s internal structure, will also create clear deviations from the baseline.

- High-Frequency Region (200 kHz – 2 MHz): This region is sensitive to the inter-turn capacitance and the self-inductance of smaller sections of the winding. It is particularly useful for detecting localized problems like conductor tilting, issues with the tap changer windings, and incipient inter-turn faults.

When a post-fault SFRA trace is compared to the baseline, a deviation in the mid-to-high frequency range is a strong indicator of winding movement. The larger the deviation, the more severe the physical damage. This allows asset managers to make informed decisions—is the transformer safe to re-energize, or does it require immediate internal inspection and repair?

Case Study: Post-Fault Analysis of a Distribution Transformer

Consider a 10 MVA distribution transformer that has experienced a close-in line-to-ground fault. After the fault is cleared, standard electrical tests like winding resistance and turns ratio show no anomalies. The transformer appears healthy. However, the utility, following best practices, decides to perform an SFRA test before re-energizing the asset.

The results are revealing. When the new SFRA traces are compared to the commissioning baseline from five years prior, Phase A and Phase C show perfect correlation. The traces lie directly on top of each other. The trace for Phase B, however, shows a significant deviation starting around 10 kHz and continuing up to 500 kHz. There is a clear shift in the resonant frequencies, with the new trace diverging from the baseline by several decibels.

This is a classic sign of winding deformation. The low-frequency response is normal, indicating the core is likely fine. The high-frequency response shows some minor shifts, but the major discrepancy is in the mid-frequency band. This suggests a bulk movement of the winding, likely radial deformation caused by the immense hoop stress during the fault. Based on this SFRA data, the utility makes the call to detank the transformer for an internal inspection. Inside, they find that the inner low-voltage winding on Phase B has been pushed inwards, with several conductors visibly deformed. The SFRA test successfully identified a critical mechanical failure that other tests missed, preventing a likely catastrophic in-service failure down the road.

Fault #2: Core-Related Problems

While the windings are often seen as the active heart of a transformer, the core is its essential skeleton. The core’s job is to provide a low-reluctance path for the magnetic flux, efficiently coupling the primary and secondary windings. Any disruption to the core’s integrity can have serious consequences, and SFRA provides a unique window into its health.

The Heart of the Transformer: Core Integrity

A transformer core is constructed from stacks of thin, silicon steel laminations. Each lamination is coated with an insulating varnish. This construction is vital to minimize energy losses, specifically eddy currents. If the laminations were to make electrical contact with each other (a “shorted lamination”), circulating currents would be induced, creating intense localized heating that could damage the core and break down the transformer oil.

The entire core assembly is held together under high pressure by a mechanical clamping structure, often called the core frame or yokes. This structure ensures that the core remains a solid, vibration-free unit. Problems can arise from several sources:

- Core Deformation: Severe fault currents or mechanical shocks can cause the core structure itself to shift or bend.

- Shorted Laminations: The insulating varnish between laminations can fail due to age, overheating, or mechanical damage, causing shorts.

- Poor Core Grounding: The core is typically grounded at a single point to prevent it from accumulating a static charge. A faulty or multiple-point ground can create closed loops for stray flux, leading to overheating.

- Loosening of Clamping Structure: Over time, vibrations and thermal cycling can cause the bolts and clamps holding the core together to loosen, leading to increased audible noise and potential damage to the core laminations.

Detecting Core Deformation and Shorted Laminations

Core-related issues primarily affect the main magnetizing inductance of the transformer. Think of the core as the primary pathway for magnetic energy. If this pathway is compromised—either by a physical deformation or by shorted laminations that create counter-magnetic fields—the overall inductance will change.

A sweep frequency response analyzer is exquisitely sensitive to this change. The behavior of the SFRA trace at very low frequencies (typically below 2 kHz) is almost entirely governed by the magnetizing inductance of the core. A healthy core provides a very high inductance, which results in a characteristic steep upward slope on the SFRA magnitude plot at the start of the frequency sweep.

If there is a problem like a shorted lamination or a grounding issue, the magnetizing inductance will decrease. This change appears on the SFRA trace as a shift of the entire low-frequency portion of the curve to the right. The steep initial slope will begin at a higher frequency compared to the baseline measurement. The magnitude of this shift can give an indication of the severity of the core problem.

Interpreting Low-Frequency Deviations

When an analyst sees a deviation between the current SFRA trace and the baseline exclusively in the low-frequency region (e.g., below 2 kHz), their suspicion immediately turns to the core or its grounding.

- A consistent shift to the right across all phases: This might indicate a systemic issue, such as residual magnetism in the core from a previous DC test (like a winding resistance measurement). It is a common practice to demagnetize the core before an SFRA test to avoid this ambiguity.

- A shift in only one phase: This is more indicative of a localized problem, such as a developing short between laminations or an issue with the clamping pressure in one specific area.

- An erratic or noisy low-frequency response: This can sometimes point to a poor core ground connection. The connection might be intermittent, causing the inductance to fluctuate and creating a non-repeatable trace.

The ability of the sweep frequency response analyzer to separate core-related issues from winding-related issues is one of its greatest strengths. While a winding deformation primarily affects the mid and high frequencies, core problems leave their distinct signature at the very beginning of the sweep. This separation is something that few other diagnostic tests can achieve with such clarity.

The Subtle Art of Grounding During Tests

The interpretation of low-frequency data is heavily dependent on proper test setup, especially grounding. As noted by experts at Doble Engineering, poor grounding practices are a common source of error in SFRA testing.

The core, the tank, and the SFRA instrument itself must all be connected to a single, solid ground point. This creates an equipotential plane and ensures that the measurements are not corrupted by stray currents or differences in ground potential. If the instrument is grounded to a different point than the transformer tank, a ground loop can be created. This loop can act like an antenna, picking up noise, or it can introduce its own inductance into the measurement circuit, distorting the low-frequency response and mimicking the signature of a core fault.

Therefore, the first step in diagnosing a low-frequency deviation is always to double-check the test setup. Were the grounding procedures followed exactly as they were for the baseline test? Are the ground leads short, and are the connections clean and tight? Only after confirming the integrity of the setup can an analyst confidently attribute a low-frequency shift to a genuine problem within the transformer’s core. This meticulous attention to detail is what separates a confusing measurement from a clear, actionable diagnosis.

Fault #3: Inter-Turn and Inter-Winding Short Circuits

Within the complex architecture of a transformer, the insulation system is the unsung hero. Miles of paper and gallons of oil work in concert to keep high voltages safely contained. When this insulation begins to fail, leading to short circuits between conductors, the transformer is on a path to failure. Detecting these faults in their infancy is a significant challenge, and one where SFRA truly excels.

The Domino Effect of Insulation Failure

A transformer winding is made of thousands of turns of copper wire, each wrapped in a paper insulation. A short circuit can occur between adjacent turns (an inter-turn fault) or between the high-voltage and low-voltage windings (an inter-winding fault).

These faults often start small. A tiny carbon track might form across the insulation due to moisture or overheating. At first, this might only be a resistive short, causing minimal disruption. However, the current flowing through this small short generates more heat, further degrading the surrounding insulation. This process can cascade, with the small short quickly developing into a low-impedance, “bolted” fault involving multiple turns.

Once a section of the winding is shorted out, it effectively acts like a secondary winding with a very low impedance load. This causes massive currents to flow in the shorted loop, generating intense localized heat. This heat can rapidly boil the surrounding oil, damage the winding conductors, and lead to a violent, explosive failure of the transformer. Detecting the fault before it escalates from a minor insulation weakness to a major short is therefore of the utmost importance.

Why Conventional Tests Might Miss These Faults

Detecting an incipient short circuit with traditional electrical tests can be very difficult.

- Winding Resistance Test: A standard DC winding resistance measurement may not detect a short involving only one or two turns. The change in the total resistance of the winding is so minuscule that it is often lost within the measurement tolerance of the instrument or masked by temperature variations.

- Transformer Turns Ratio (TTR) Test: Similarly, a TTR test measures the ratio of the total number of turns in the high-voltage winding to the low-voltage winding. Shorting out a few turns out of thousands will cause a change in the ratio that is often too small to be reliably detected by a standard TTR set.

- Insulation Resistance Test: This test is excellent for measuring the overall quality of the insulation between windings and ground, but it cannot detect a short circuit that is contained entirely within a single winding (an inter-turn fault).

These tests are still valuable parts of a maintenance program, but they have a blind spot when it comes to early-stage internal shorts. The sweep frequency response analyzer fills this gap.

The High-Frequency Signature of a Short Circuit

A short circuit fundamentally alters the electromagnetic properties of the winding. When a turn or a section of a winding is shorted, it effectively removes that part of the inductance from the circuit. At the same time, it dramatically changes the capacitance distribution within the winding. This combined change in L and C has a profound effect on the winding’s frequency response, particularly in the high-frequency region.

Every winding has a series of natural resonant frequencies, which appear as sharp peaks and valleys on the SFRA plot. These resonances are determined by the winding’s inductance and capacitance. When a short circuit occurs, it changes these L and C values, causing the resonant frequencies to shift.

Typically, an inter-turn short circuit will cause the first major resonant peak in the high-frequency range to shift to a higher frequency. The shorted section reduces the effective inductance of the winding, and since resonant frequency is inversely proportional to the square root of inductance and capacitance (f ≈ 1/√(LC)), a lower inductance results in a higher resonant frequency. This shift provides a clear and unambiguous indication of a short circuit that other tests might miss. The analysis of the plot becomes a search for these tell-tale frequency shifts when compared to the baseline signature.

A Comparative Look: SFRA vs. Other Electrical Tests

To better situate the unique role of the sweep frequency response analyzer, it is helpful to compare its capabilities with other common diagnostic methods for transformers.

| Diagnostic Test | Principle of Operation | Primary Faults Detected | Strengths | Limitations |

|---|---|---|---|---|

| Sweep Frequency Response Analysis (SFRA) | Measures winding transfer function over a wide frequency range (AC). | Winding deformation, core issues, inter-turn shorts, open circuits, bad connections. | Highly sensitive to mechanical changes and incipient faults. Provides a graphical “fingerprint.” | Requires a baseline for comparison. Interpretation can be complex. |

| Winding Resistance | Injects a DC current and measures the voltage drop to calculate resistance. | Poor connections, broken conductors (open circuit), severe short circuits. | Simple, well-understood test. Good for verifying connection integrity. | Insensitive to minor inter-turn shorts and most mechanical deformations. Temperature dependent. |

| Relación de vueltas del transformador (TTR) | Applies a voltage to one winding and measures the induced voltage on the other. | Incorrect winding taps, severe short circuits, open windings. | Verifies the fundamental voltage relationship of the transformer. | Insensitive to most mechanical faults and minor short circuits. |

| Insulation Resistance / Megger | Applies a high DC voltage and measures the leakage current. | Degraded insulation between windings and ground, moisture contamination. | Assesses the overall condition of the bulk insulation system. | Cannot detect inter-turn faults. Provides a single value, not a detailed picture. |

| Dissolved Gas Analysis (DGA) | Analyzes gases dissolved in the transformer oil to identify thermal or electrical stress. | Overheating, arcing, partial discharge. | Can detect faults in their very early stages by identifying byproduct gases. | Does not locate the fault. It indicates a problem type but not its position or severity. |

As the table illustrates, each test provides a different piece of the puzzle. SFRA’s unique strength is its direct sensitivity to the physical geometry of the transformer’s active parts, making it the premier tool for detecting mechanical damage and the subtle changes caused by internal short circuits. A comprehensive condition assessment program, like those advocated by leading industrial service providers such as Voltage-Tester, often uses a combination of these methods to build a complete picture of the transformer’s health.

Fault #4: Open Windings and Poor Connections

While short circuits represent a dangerous new path for current, an open circuit represents a complete break. Both conditions are fatal to a transformer’s operation. An open winding or a high-resistance connection can prevent the transformer from functioning correctly and can create hazardous situations. SFRA testing provides a definitive method for identifying these types of connection failures.

The Peril of a Broken Circuit

An open circuit fault occurs when a conductor within a winding physically breaks or a connection point fails completely. This can happen for several reasons:

- Manufacturing Defects: A poorly brazed joint connecting conductor strands or connecting the winding to the bushing lead might fail over time.

- Vibrations: Constant operational vibrations or severe jolts during transportation can fatigue a connection point, causing it to crack and eventually separate.

- Thermal Stress: The constant expansion and contraction of conductors due to load cycling can put stress on connection points, leading to failure.

- Fault-Related Forces: The same violent forces that cause winding deformation can also be strong enough to snap a conductor or pull a connection apart.

The result of an open circuit is a complete loss of current flow through the affected winding. A less severe but equally problematic issue is a high-resistance connection. Here, the joint has not failed completely but has developed a high resistance due to corrosion, looseness, or contamination (coking). This bad connection will generate intense heat during operation, potentially leading to a fire or thermal runaway failure.

Identifying Open Windings with SFRA

The signature of an open winding on a sweep frequency response analyzer plot is perhaps the most dramatic and easiest to interpret of all fault types. An open circuit fundamentally changes the nature of the winding from a low-impedance inductive path to a very high-impedance capacitive path at low frequencies.

When the SFRA test is performed on a healthy winding, the low-frequency portion of the trace shows a response dominated by the core inductance, as previously discussed. However, if there is an open circuit within the winding being tested, this inductive path to ground is broken. The instrument now only “sees” the capacitance of the winding to the core and tank.

This results in a massive deviation from the baseline. Instead of the typical upward-sloping inductive response at low frequencies, the trace will look completely different, often showing a flat, capacitive response at a very low magnitude. All the characteristic resonant peaks that define the healthy winding’s signature will disappear, replaced by a completely different and often unrecognizable pattern. The difference between the baseline and the test trace is not a subtle shift of a few dB; it is a total divergence. This makes the diagnosis of an open winding using a high-quality sweep frequency response analyzer exceptionally clear.

Bushing and Tap Changer Connection Issues

Problems don’t always occur deep within the main winding body. The connection points at the interfaces—where the winding connects to the tap changer or to the high-voltage bushings—are also common failure points.

- Bushing Connections: The lead from the top of the winding to the bottom of the bushing is a critical connection. If this connection becomes loose or corroded, it introduces a series resistance and can alter the capacitance at the very end of the winding. This might appear on the SFRA trace as a deviation primarily in the highest frequency region, as this part of the spectrum is most sensitive to the conditions at the physical ends of the winding.

- Tap Changer Connections: On-load tap changers (OLTCs) and de-energized tap changers (DETCs) are mechanical switches with multiple contacts. A poor contact at the selected tap position can introduce a high resistance or even an intermittent open circuit. An SFRA test performed on a specific tap setting will be sensitive to the quality of that connection. Comparing the SFRA response on a suspect tap position to the response on an adjacent, healthy tap position can often pinpoint the problem.

Best Practices for Test Lead Connections

The sensitivity of SFRA to connection issues highlights the absolute necessity of using proper and consistent test lead connections. The way the test leads from the SFRA instrument are connected to the transformer bushings can have a significant impact on the measured response, especially at high frequencies.

As detailed in industry best practices, several common mistakes can lead to non-repeatable results and misinterpretation:

- Using Long Test Leads: Long leads add extra inductance and capacitance to the measurement circuit, which can shift the high-frequency response. Leads should be as short as possible.

- Inconsistent Braiding of Leads: The source and measurement leads often have a shield or ground braid. The way this braid is connected and routed must be identical for every test. For consistency, it is often recommended to braid the source and measurement leads together.

- Poor Contact at the Bushing: The clamp connecting the test lead to the bushing terminal must be clean and tight to ensure a low-resistance connection. A dirty or loose clamp can mimic the signature of a fault within the transformer.

To ensure reliable diagnostics, the test procedure must be meticulously documented during the baseline measurement. This documentation should include photographs showing the exact routing and connection of the test leads. For all future tests, the technician must replicate this setup precisely. This procedural rigor is what allows SFRA to reliably distinguish between a real internal transformer problem and a simple measurement setup error.

Fault #5: Issues with Bushings and Tap Changers

While much of the focus in SFRA is on the core and windings, the ancillary components connected to them are just as critical. Bushings provide the insulated pathway for electricity to enter and exit the transformer tank, and tap changers allow for fine-tuning of the output voltage. Failures in these components can disable a transformer, and SFRA can provide valuable insights into their condition.

The Gateways to the Transformer: Bushing Integrity

A high-voltage bushing is a complex component in its own right, often consisting of a central conductor surrounded by layers of oil-impregnated paper or resin-bonded paper, with a porcelain or composite external insulator. Its job is to provide both structural support and high electrical insulation.

A common failure mode in condenser-type bushings is the shorting of one or more of the internal capacitive layers. This changes the bushing’s overall capacitance and disrupts the smooth distribution of the electrical field along its length. This change in capacitance can be detected by an SFRA test.

When an SFRA test is configured to measure the response of a winding (an end-to-end measurement), the bushing’s capacitance is part of the overall circuit being measured. A change in the bushing’s capacitance will therefore cause a shift in the SFRA trace, typically at higher frequencies. By comparing the response of the three phases, if one phase shows a deviation at the high-frequency end, it could be indicative of a problem in that phase’s bushing. While other tests like power factor/tan delta are the primary tools for bushing diagnostics, SFRA can provide a valuable corroborating piece of evidence.

How Tap Changer Problems Manifest in SFRA Traces

The tap changer is the only moving part inside most power transformers, making it a major point of potential failure. It is a mechanical switch that changes the transformer’s turns ratio by connecting to different “taps” along the winding. Problems can include:

- Contact Coking/Pitting: Arcing during operation can cause the metal contacts to become pitted or coated with carbon (coked), leading to high contact resistance.

- Misalignment: Mechanical wear or failure can cause the tap changer to not align properly on the selected contact.

- Open Circuits: A broken lead or failed contact can create an open circuit.

SFRA is an excellent tool for assessing the health of the tap changer and its associated tap winding. The tap winding is a small section of the main winding with multiple connection points, and it has its own characteristic frequency response. A common diagnostic technique is to perform an SFRA sweep on each individual tap position and overlay the results.

In a healthy tap changer, the traces for each tap position will show a consistent pattern. The resonant frequencies will shift slightly and predictably from one tap to the next as the amount of winding in the circuit changes. However, if one tap position has a bad contact, its SFRA trace will show a significant deviation from the family of curves. This provides a clear visual indication of which specific tap contact is faulty.

A Practical Guide to Setting Up the Test

The choice of test connection is crucial as it determines which part of the transformer’s internal network is being investigated. Different connections are sensitive to different types of faults.

| Test Configuration | Source Connection | Measurement Connection | Primary Faults Detected | Explanation |

|---|---|---|---|---|

| End-to-End Open Circuit | H1 | H0 (Neutral) | Open circuits, inter-turn shorts, and general winding integrity. | This is the most common test. It measures the response of a single winding and is sensitive to changes within that winding. |

| End-to-End Short Circuit | H1 | H0 (Neutral) | Winding deformation (especially radial), core issues. | The secondary winding (e.g., X1-X0) is shorted. This removes the influence of core inductance and focuses the test on leakage inductance, which is sensitive to winding geometry. |

| Inter-Winding | H1 | X1 | Inter-winding capacitance, winding displacement relative to each other. | Measures the transfer function between the primary and secondary windings. Highly sensitive to any change in the physical relationship between the two windings. |

| Tap Winding | H1 | Tap 1, Tap 2, etc. | Tap changer contact issues, integrity of the tap winding itself. | The test is repeated for each tap position to check for consistency and identify faulty contacts. |

By performing a suite of these tests, a complete diagnostic picture of the transformer can be assembled. For example, the end-to-end short circuit test is the most sensitive to radial winding deformation, while the inter-winding test is best for detecting axial shifting of one winding relative to another. An experienced analyst will use a combination of these configurations to not just detect a fault, but to pinpoint its location and nature with remarkable accuracy. This level of insight is what makes the sweep frequency response analyzer an indispensable tool for modern asset management.

Frequently Asked Questions (FAQ)

1. How often should I perform an SFRA test? A baseline test should be performed when the transformer is new (at the factory or upon commissioning). After that, SFRA is typically performed after a suspected stress event, such as a major external short circuit, a lightning strike, or a difficult relocation. It is also a valuable part of a time-based condition assessment program, perhaps every 5-10 years, depending on the criticality of the asset.

2. Can SFRA testing predict the remaining life of a transformer? No, SFRA is not a life-assessment tool. It is a condition-assessment tool. It cannot predict how many years of life a transformer has left. Instead, it provides a snapshot of the transformer’s current mechanical and electrical integrity. It tells you if the transformer has sustained damage, which, if left unaddressed, could significantly shorten its life.

3. What’s the difference between SFRA and a standard frequency response analysis? The terms are often used interchangeably. “Sweep Frequency Response Analysis” (SFRA) is the more precise term, emphasizing that the test sweeps through a range of discrete frequencies. This is distinct from an older method, impulse frequency response analysis (IFRA), which used a high-voltage impulse to generate a broad spectrum of frequencies at once. SFRA is the modern, more repeatable, and safer standard.

4. Is SFRA a “pass/fail” test? Not in a simple sense. The interpretation of SFRA results is based on comparison and requires expertise. There are no universal “pass/fail” limits. A deviation from the baseline is an indication of a change. The analyst must then use the magnitude, frequency range, and type of deviation, often in conjunction with data from other tests, to assess the severity of the problem and decide on a course of action.

5. What are the main challenges when interpreting SFRA results? The biggest challenge is the absence of a good baseline reference. Without it, interpretation relies on phase-to-phase or sister-unit comparisons, which can be less conclusive. Other challenges include the influence of residual magnetism, inconsistent test setups (especially grounding and lead dressing), and understanding the complex interaction of various fault types that might occur simultaneously.

6. Can temperature affect SFRA test results? The effect of temperature on SFRA results is generally considered minor compared to its significant impact on tests like winding resistance or power factor. The mechanical geometry and inductances/capacitances of the windings do not change significantly with normal temperature variations. However, for the highest level of precision, it is good practice to record the oil temperature and perform comparative tests at similar temperatures whenever possible.

7. Do I need to de-energize the transformer for SFRA? Yes, absolutely. The transformer must be completely de-energized, disconnected from all external high and low voltage lines, and properly grounded before any SFRA test leads are connected. It is a non-intrusive offline test.

Conclusión

The power transformer stands as a silent, steadfast component of the electrical grid, yet it is vulnerable to internal injuries that can lead to sudden and violent failure. The sweep frequency response analyzer acts as a powerful stethoscope, allowing us to listen to the internal condition of this critical asset without invasive surgery. By creating a detailed frequency fingerprint, SFRA can reveal the subtle signs of winding deformation, the hidden problems in the core, the beginnings of a short circuit, and the weakness of a failing connection. It translates the complex language of inductance and capacitance into a clear, graphical story of the transformer’s health.

In an era where grid reliability is more important than ever, moving from a reactive to a predictive maintenance strategy is not just an option; it is a necessity. The sweep frequency response analyzer is a cornerstone of this modern approach. It empowers engineers and asset managers to make informed, data-driven decisions—to intervene before a minor mechanical shift becomes a catastrophic failure, to extend the life of valuable assets, and to ensure the stable, uninterrupted flow of power that underpins our society.