Proven Guide to Sweep Frequency Response Analyzers: Detect 5 Critical Transformer Faults Before They Happen

novembre 5, 2025

Abstract

The operational integrity of power transformers is fundamental to the stability of electrical grids. Failures can lead to catastrophic outages, significant financial loss, and safety hazards. Sweep Frequency Response Analysis (SFRA) has emerged as a powerful and sensitive diagnostic method for assessing the mechanical and electrical condition of a transformer's active parts without internal inspection. This analysis examines the principles, procedures, and interpretive frameworks associated with Sweep Frequency Response Analyzers. By injecting a low-voltage sinusoidal signal across a wide frequency spectrum and measuring the response, SFRA creates a unique "fingerprint" of the transformer. Deviations from this baseline fingerprint, established when the transformer was known to be in good condition, indicate internal structural changes. The method is particularly effective in detecting winding deformations, core displacements, faulty connections, and shorted turns, often resulting from manufacturing defects, transportation stresses, or in-service faults. This text provides a comprehensive exploration of SFRA methodology, from the theoretical underpinnings of frequency domain analysis to the practical application of the test and the nuanced interpretation of its results.

Key Takeaways

- Establish a baseline SFRA trace for every new or repaired transformer.

- Compare subsequent tests against the baseline to detect internal changes.

- Analyze low-frequency ranges for core problems and magnetizing inductance.

- Examine mid-frequency bands for signs of winding deformation.

- Use high-frequency data to diagnose issues with leads and tap changers.

- Integrate data from Sweep Frequency Response Analyzers into a holistic maintenance plan.

- Correlate SFRA results with other diagnostic tests for a confident diagnosis.

Table of Contents

- The Silent Sentinel of Transformer Health

- Understanding the Core Principle: What is Frequency Response?

- The Sweep Frequency Response Analyzer (SFRA) in Practice

- Detecting 5 Critical Faults: Interpreting the SFRA Signature

- SFRA Data Analysis: From Raw Data to Actionable Insights

- The Broader Context: SFRA in a Comprehensive Asset Management Program

- Frequently Asked Questions (FAQ)

- Conclusion

- References

The Silent Sentinel of Transformer Health

A power transformer does not often announce its impending failure. It stands as a stoic, humming giant in a substation, a critical node in the vast network that powers our cities, industries, and homes. Yet, within its steel tank, unseen forces are constantly at play. The immense magnetic fields, thermal cycles, and the ever-present threat of through-fault currents can exert tremendous mechanical stress on its internal structure. A failure is not merely an inconvenience; it represents a multi-million-dollar loss, months of downtime, and a potential threat to grid stability across an entire region. For asset managers in developing economies or remote industrial sites, from the mining operations in South Africa to the sprawling urban centers of Southeast Asia, the reliability of these assets is paramount.

Imagine the challenge. You are responsible for a fleet of transformers, some new, some decades old. How can you gain confidence in their internal condition without a costly, time-consuming, and risky internal inspection? How do you differentiate a healthy unit from one that has suffered subtle but dangerous damage during transportation or a recent system fault? The answer lies in moving beyond simple electrical tests toward a more profound understanding of the transformer's physical integrity.

This is the role of the Sweep Frequency Response Analyzer, or SFRA. It functions like a stethoscope for the transformer, listening not to a heartbeat, but to its unique electrical resonance across a spectrum of frequencies. By creating a detailed "fingerprint" of the transformer's active part—the core, windings, and connections—an SFRA test provides an unparalleled view of its mechanical health. It is a non-invasive procedure that can reveal the secret story of what has happened inside the tank, detecting problems long before they escalate into a catastrophic failure. This guide explores the world of Sweep Frequency Response Analyzers, moving from the foundational theory to the practical art of interpreting their results to safeguard our most vital electrical assets.

Understanding the Core Principle: What is Frequency Response?

To appreciate the power of an SFRA test, one must first grasp the concept of frequency response. Think of a musical instrument, perhaps a guitar. Plucking a string produces a specific note, which is its fundamental frequency. It also produces a series of fainter, higher-pitched overtones. The unique combination of the fundamental note and its overtones is what gives the guitar its characteristic sound, or timbre, allowing us to distinguish it from a violin playing the same note. The instrument's physical construction—the type of wood, the tension of the strings, the shape of the body—determines this unique acoustic signature.

A transformer, in a similar way, has a unique electrical signature. While it is designed to operate at a single power frequency (50 or 60 Hz), its complex internal structure of windings and core means it behaves differently when subjected to a wide range of other frequencies. An SFRA test does exactly this: it "plucks" the transformer not with a finger, but with a low-voltage electrical signal, and listens to the "sound" it makes across a vast range of frequencies.

The Transformer as a Complex RLC Circuit

At its heart, a power transformer is a network of resistors (R), inductors (L), and capacitors (C).

- Resistance (R) comes from the electrical resistance of the copper or aluminum winding conductors.

- Inductance (L) is the primary property of the windings. The main inductance is determined by the magnetic core, while leakage inductance is determined by the geometry of the windings.

- Capacitance (C) exists everywhere: between adjacent turns of a winding (inter-turn), between different layers of a winding (inter-layer), between the windings themselves (inter-winding), and between the windings and grounded parts like the core and the tank (winding-to-ground).

At the nominal power frequency, the inductive properties dominate. However, as the frequency of the applied signal increases, the capacitive elements begin to have a much greater effect. The intricate physical arrangement of these R, L, and C components creates a complex circuit with a series of resonant peaks and troughs at specific frequencies. The exact position and magnitude of these resonances are a direct function of the transformer's physical construction. Any change to the physical structure—a winding moving by a few millimeters, a core component shifting, or a connection loosening—will alter the inductance or capacitance at that location. This, in turn, shifts the resonant frequencies, changing the transformer's "timbre."

Creating the Fingerprint: The Sweep and the Measurement

The SFRA test methodically generates this fingerprint. A Sweep Frequency Response Analyzer applies a sinusoidal voltage of a known, constant level to one terminal of the transformer. It then "sweeps" the frequency of this signal, starting from a low frequency (e.g., 20 Hz) and moving up to a high frequency (e.g., 2 MHz).

Simultaneously, the instrument measures the voltage signal at another terminal. The "response" is the ratio of the output voltage to the input voltage (Vout/Vin). This ratio, expressed in decibels (dB), is plotted against the frequency on a logarithmic scale. The resulting graph of jagged peaks and valleys is the transformer's unique frequency response signature.

This signature is the baseline, the "as-new" or "as-healthy" condition of the transformer. The entire diagnostic power of the SFRA method hinges on the principle of comparison. A test performed today is compared against that baseline. If the two traces overlay perfectly, it gives high confidence that the transformer's internal geometry has not changed. If they deviate, it is a clear alarm that something has shifted, and the location and nature of the deviation provide clues to the type and severity of the fault.

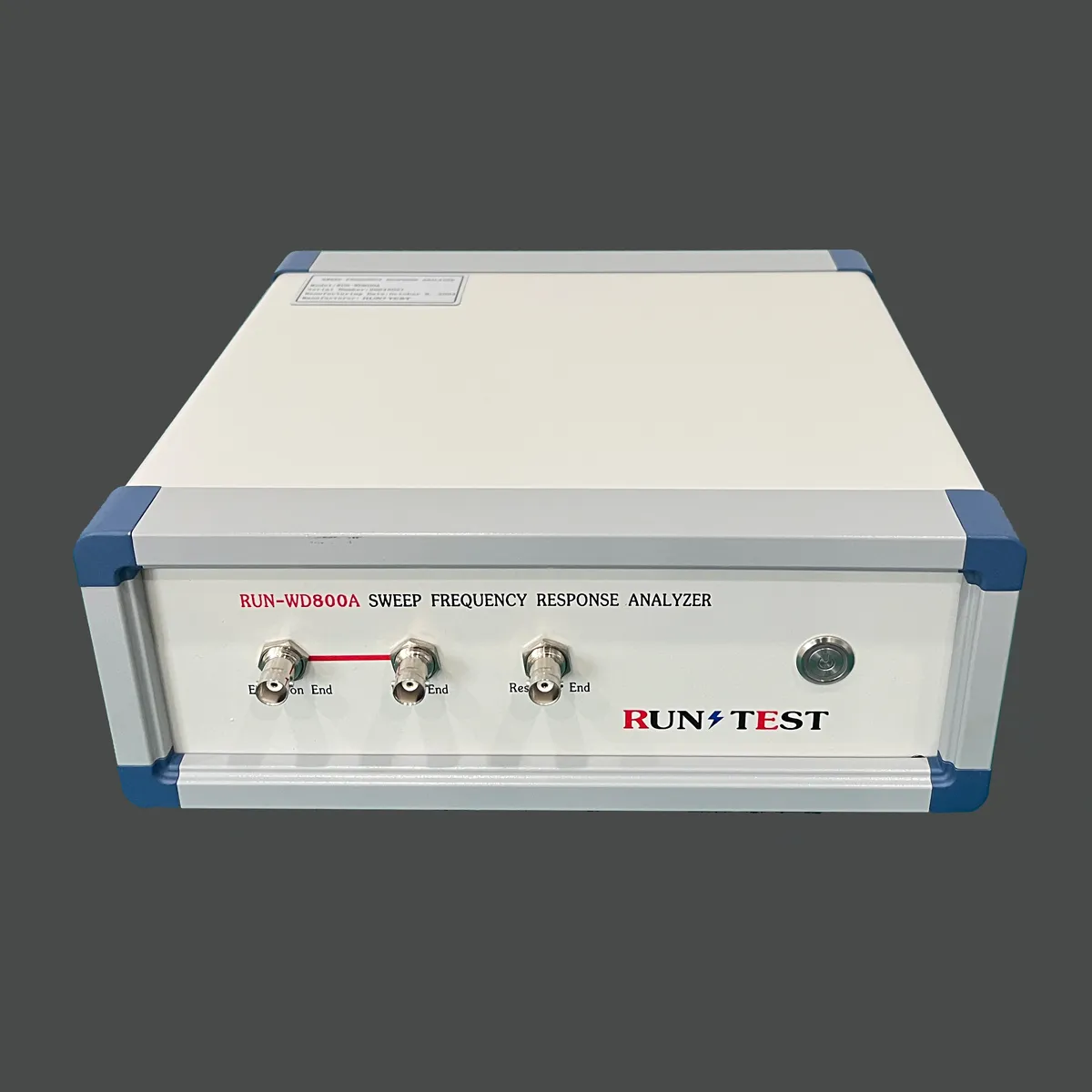

The Sweep Frequency Response Analyzer (SFRA) in Practice

Transitioning from the theory of frequency response to a practical field test involves a disciplined procedure and specialized equipment. The goal is to produce a repeatable and reliable measurement that accurately reflects the transformer's internal state, free from external interference or measurement errors. Modern advanced sweep frequency response analyzers are sophisticated instruments designed for field use, combining precision signal generation with robust data acquisition.

Components of an SFRA System

A typical SFRA test setup consists of several key components:

- The Analyzer Unit: The core of the system. It contains the signal generator, the measurement channels, and the processing hardware/software to control the sweep and plot the results.

- Source Cable: A coaxial cable that carries the low-voltage swept frequency signal from the analyzer to the transformer terminal. It is specifically designed to maintain signal integrity over a wide frequency range.

- Measurement Cable: A matched coaxial cable that carries the response signal from a second transformer terminal back to the analyzer.

- Clamps and Connectors: Specially designed clamps are used to connect the cables to the transformer bushings. Proper connection is vital for a good measurement, requiring short, direct paths and solid ground connections.

- Grounding Braids: Short, wide, flat braided straps are used to connect the cable shields to the transformer's ground point. Using long, thin ground wires can introduce inductance, which will corrupt the high-frequency portion of the measurement.

The Test Procedure: A Step-by-Step Walkthrough

Performing an SFRA test requires a methodical approach to ensure consistency and comparability of results.

- Preparation and Safety: The transformer must be de-energized and fully isolated from the power system. All terminals must be disconnected and grounded. Safety is the first priority; follow all local lockout/tagout procedures. The surface of the bushings should be cleaned to ensure a good electrical connection.

- Test Plan: Before starting, a test plan is established, detailing which measurements will be performed. For a three-phase transformer, a series of tests are conducted to assess each winding from different perspectives. The table below outlines a standard set of tests.

- Connecting the Analyzer: The source and measurement cables are connected according to the test plan. For example, for an end-to-end open-circuit test on the high-voltage winding of Phase A, the source cable might be connected to the H1 bushing and the measurement cable to the H0 bushing. The cable shields are connected to the transformer ground point using short, flat braids.

- Executing the Sweep: The operator uses the analyzer's software to initiate the frequency sweep. The instrument automatically sweeps from low to high frequency, recording the response at hundreds or thousands of points along the way. The process for a single measurement typically takes less than a minute.

- Data Storage: The resulting trace is saved and clearly labeled with the transformer ID, date, temperature, and specific test configuration (e.g., "HV Winding, H1-H0, Open Circuit").

- Repeating for All Configurations: The process is repeated for all tests in the plan, covering all windings and phases.

A key aspect of SFRA testing is repeatability. The test setup, including cable routing and grounding points, should be replicated as closely as possible each time the transformer is tested. Documenting the setup with photographs is a highly recommended practice.

| Test Name | Source Connection | Measurement Connection | Other Windings | Primary Purpose |

|---|---|---|---|---|

| End-to-End Open-Circuit | HV Winding Start (e.g., H1) | HV Winding End (e.g., H0) | LV windings are left open | Assesses the main winding, inter-turn faults, and the magnetic core. |

| End-to-End Short-Circuit | HV Winding Start (e.g., H1) | HV Winding End (e.g., H0) | LV windings are shorted | Focuses on winding deformation and leakage inductance by removing the core's influence. |

| Capacitive Inter-Winding | HV Winding Start (e.g., H1) | LV Winding Start (e.g., X1) | All terminals left open | Measures the capacitance between the HV and LV windings. Sensitive to relative movement. |

| Inductive Inter-Winding | HV Winding Start (e.g., H1) | HV Winding Start (e.g., H2) | LV windings are shorted | Compares the leakage inductance of different phases. |

Detecting 5 Critical Faults: Interpreting the SFRA Signature

The true skill in using Sweep Frequency Response Analyzers lies in interpreting the graphical results. A deviation between a current measurement and the baseline fingerprint is a clear signal of a change, but what kind of change? The frequency range where the deviation occurs is the primary clue to diagnosing the specific problem. The transformer's response can be broadly divided into distinct frequency regions, each dominated by different physical components.

Understanding these regions is like learning to read a map of the transformer's interior. A problem in one geographical area (the core) will show up in a different part of the graph than a problem in another area (the winding leads).

| Gamme de fréquences | Typical Band | Dominant Component | Associated Faults |

|---|---|---|---|

| Low Frequency | 20 Hz – 2 kHz | Magnetic Core & Main Inductance | Core deformation, open circuits, shorted turns, residual magnetism. |

| Mid Frequency | 2 kHz – 200 kHz | Bulk Winding Structure | Axial and radial winding deformation, inter-winding faults. |

| High Frequency | 200 kHz – 2 MHz | Winding Leads, Tap Changer, Bushings | Poor contacts, broken connections, bushing issues, movement of leads. |

Fault 1: Core Deformation and Magnetic Circuit Issues

The low-frequency region of the SFRA trace is primarily governed by the transformer's main inductance, which is a direct function of the magnetic core. The core is a massive structure made of laminated steel sheets, and its job is to channel the magnetic flux. Any issue that affects the core's ability to do so will appear as a deviation in the low-frequency range (typically below 2 kHz).

Imagine a short circuit in the core's lamination insulation or a problem with the core ground. This creates a new path for magnetic flux, altering the overall inductance of the circuit. On the SFRA plot, this often manifests as a significant downward shift of the entire low-frequency portion of the curve and a change in the first resonant peak. Similarly, if there is a problem like an open circuit in a delta winding or a significant number of shorted turns, the magnetizing inductance changes dramatically, which is immediately visible in this frequency band. A comparison of the open-circuit test results between the three phases is particularly effective here. If two phases show identical responses but the third is shifted, it strongly points to a problem specific to that phase's magnetic circuit.

Fault 2: Winding Deformation (Axial & Radial)

The windings are the heart of the transformer. They are subjected to enormous repulsive forces during external short circuits. These forces can cause the conductors to bend and twist, leading to two main types of deformation:

- Axial Deformation: A compression or stretching of the winding along its vertical axis, like squashing a spring. This changes the spacing between winding sections.

- Radial Deformation: A buckling of the winding, either inwards towards the core or outwards towards the tank, like a can being crushed. This changes the diameter of the winding.

Both types of deformation alter the intricate network of capacitances within the transformer, particularly the inter-turn and inter-disc capacitances. Because capacitance has a stronger influence at higher frequencies, these changes become visible in the mid-frequency range (roughly 2 kHz to 200 kHz).

A change in the winding's physical shape causes the resonant peaks in this region to shift. A general rule of thumb is that a decrease in capacitance (e.g., conductors moving further apart) will shift the resonance to a higher frequency, while an increase in capacitance (conductors moving closer) will shift it to a lower frequency. For example, severe radial buckling could cause a noticeable shift in multiple resonant peaks in the mid-frequency band when comparing the post-fault trace to the baseline. These are precisely the kinds of subtle but dangerous damages that can occur during rough transportation to a remote site, which might otherwise go completely undetected until a failure occurs.

Fault 3: Shorted Turns and Open Windings

While a major open circuit or a heavily shorted winding affects the low-frequency response, a small number of shorted turns creates a more localized effect. A few shorted turns create a new resonant circuit within the winding. This often introduces a new, sharp resonant null (a deep dip) in the SFRA trace, typically in the mid-to-high frequency range. The exact frequency of this new null depends on the location of the short within the winding. This is a very distinct signature and is one of the classic indicators that SFRA technicians look for.

An open winding, such as a broken conductor, will cause a dramatic change in the overall inductance, leading to a massive deviation across almost the entire frequency spectrum compared to the baseline. The trace might appear completely different, indicating a catastrophic failure within that winding path.

Fault 4: Faulty Tap Changer Connections

On-load tap changers (OLTCs) and de-energized tap changers (DETCs) are mechanical devices used to adjust the transformer's voltage ratio. They are the only moving parts inside a transformer and are a common source of failure. A poor connection at a tap contact introduces extra resistance and can alter the local inductance and capacitance.

This type of fault is often most visible in the higher frequency ranges (above 200 kHz). The main windings act as a transmission line for the high-frequency test signal, and a problem at the tap changer creates an impedance mismatch. This mismatch causes reflections and changes the shape of the frequency response curve. A common diagnostic technique is to perform SFRA tests on several different tap positions. If the traces for most tap positions are consistent but one position shows a significant deviation, it is a very strong indication of a contact problem on that specific tap. This targeted information allows maintenance crews to focus their repair efforts precisely where they are needed.

Fault 5: Bushing and Lead Connection Problems

The highest frequency part of the SFRA spectrum (above roughly 500 kHz and up to 2 MHz) is most sensitive to the geometry and condition of the components closest to the measurement terminals: the bushings and the internal connection leads. The main windings have a large inductance that tends to filter out very high-frequency signals, so the response in this range is dominated by the capacitance of the bushings and the inductance of the leads that run from the top of the winding to the bushings.

A cracked bushing, moisture ingress, or a loose or broken internal lead will change the local capacitance or inductance. This will cause the high-frequency portion of the measured trace to deviate from the baseline. For example, if a lead has come loose and is now closer to the grounded tank wall, the capacitance to ground will increase, shifting the high-frequency response downwards. Because these issues can be precursors to a catastrophic flashover, their early detection through a transformer diagnostic equipment test is exceptionally valuable. Comparing the response of the three phases is again a powerful tool; if the H1, H2, and H3 bushings are identical, their high-frequency SFRA traces should be nearly perfect overlays of one another.

SFRA Data Analysis: From Raw Data to Actionable Insights

Collecting SFRA data is only half the battle. Transforming those jagged lines on a screen into a confident diagnosis requires a systematic approach to analysis, combining technical knowledge with an investigative mindset. The core of SFRA interpretation is not about analyzing a single trace in isolation, but about comparing it to reference traces.

The Power of Comparison: Baseline vs. Subsequent Tests

The most powerful use of SFRA is as a condition monitoring tool over the transformer's life. The first test, performed at the factory, after delivery, or after a major repair, serves as the "birth certificate" or baseline fingerprint. This trace represents the transformer in a known healthy state.

Every subsequent test performed during routine maintenance is then overlaid on this baseline.

- No Change: If the new trace perfectly matches the baseline, it provides a very high degree of confidence that the mechanical integrity of the transformer's active parts remains unchanged.

- Minor Deviation: Small, subtle shifts might be attributable to differences in oil temperature, moisture content, or minor measurement variations. These warrant observation but may not require immediate action.

- Significant Deviation: A clear, undeniable difference between the traces, especially in specific frequency bands as discussed previously, is a red flag. It is objective evidence that a physical change has occurred inside the transformer.

This historical comparison is the gold standard for SFRA analysis. It removes ambiguity and allows for the detection of incipient faults that develop slowly over time.

Phase-to-Phase and Unit-to-Unit Comparisons

What if you lack a baseline fingerprint for an older transformer? While not ideal, SFRA can still provide immense value. In such cases, comparison is made between the phases of the same transformer. A three-phase transformer is essentially three single-phase units built on a common core. Their physical construction is, or should be, nearly identical.

Therefore, performing the same test (e.g., an H1-H0 open-circuit test) on all three phases should yield very similar SFRA traces. The two outer phases (A and C) should be nearly identical, while the center phase (B) might show slight, predictable differences due to its different magnetic flux path. If two phases match each other but the third phase shows a dramatic deviation, it is a strong indicator of a problem in that third phase.

A further method is the "sister unit" comparison. If a substation has several identical transformers from the same manufacturing batch, the SFRA trace from a healthy unit can serve as a reference for its siblings.

Common Pitfalls in SFRA Measurement and Interpretation

While powerful, SFRA is a sensitive measurement technique. Inaccurate conclusions can be drawn if the test is not performed correctly. Awareness of common pitfalls is essential.

- Poor Grounding: Using a long, coiled wire for the ground connection instead of a short, flat braid is the most common mistake. It introduces inductance that severely distorts the high-frequency response, potentially masking real faults or creating phantom ones.

- Inconsistent Connections: Connecting to different points on the bushing terminal or routing cables differently between tests will alter the measurement. Consistency is key. Taking photos of the setup is the best way to ensure repeatability.

- Residual Magnetism: If the transformer was recently subjected to DC tests (like winding resistance), the core can become magnetized. This can shift the low-frequency portion of the trace. Demagnetizing the core before an SFRA test is recommended.

- Over-Interpretation: Not every tiny wiggle in the trace is a fault. Small variations can occur due to temperature or other benign factors. The focus should be on clear, repeatable deviations in the characteristic frequency bands that align with known fault types. Correlation with other diagnostic tests is the best way to confirm a diagnosis.

The Broader Context: SFRA in a Comprehensive Asset Management Program

A Sweep Frequency Response Analyzer is not a magic wand. It is a supremely powerful diagnostic tool, but its true value is realized when it is integrated into a holistic asset management and maintenance strategy. Relying on a single test for a high-stakes decision is rarely wise. Instead, the findings from an SFRA test should be considered alongside data from other diagnostic methods to build a complete and coherent picture of the transformer's health.

Complementary Diagnostic Tests: Building a Case

Imagine you are a detective at a crime scene. You would not rely solely on fingerprints; you would also look for footprints, witness statements, and other evidence. Similarly, diagnosing a transformer requires a multi-faceted approach.

- Analyse des gaz dissous (AGD) : DGA analyzes the gasses dissolved in the transformer oil. Certain gasses are produced by specific fault conditions like overheating (producing ethylene and ethane) or arcing (producing acetylene). If an SFRA test suggests a possible shorted turn, a DGA result showing elevated levels of these gasses would strongly corroborate the diagnosis.

- Power Factor / Tan Delta Testing: This test measures the dielectric losses in the insulation system. A rising power factor indicates deteriorating insulation, perhaps due to moisture or aging. If an SFRA test shows a deviation in the high-frequency range pointing to a bushing problem, an accompanying poor power factor result for that specific bushing would confirm the issue.

- Mesure de la résistance d'enroulement : A simple DC test that can detect poor connections, broken conductors, or issues with the tap changer contacts. If SFRA points to a tap changer problem, a winding resistance test on that tap can provide definitive confirmation of a high-resistance contact.

When the story told by the SFRA trace aligns with the stories told by DGA, power factor, and resistance tests, the diagnostic confidence becomes extremely high. This allows asset managers to move from suspicion to decisive action, such as scheduling an internal repair or replacing a faulty component.

Economic Justification: The ROI of Proactive Testing

Implementing an SFRA testing program requires an investment in equipment and training. How does one justify this cost? The answer lies in risk mitigation and the staggering cost of failure. The price of a new large power transformer can run into millions of dollars, with lead times of a year or more. The cost of an unplanned outage, including lost revenue and potential penalties, can be even higher.

Consider a scenario: An SFRA test on a critical 20-year-old transformer reveals a significant winding deformation, likely caused by a recent nearby fault. Without this information, the transformer would have remained in service until the weakened winding eventually failed under stress, causing a catastrophic failure and a prolonged outage. With the SFRA data, the asset manager can schedule a planned outage to either replace the unit or perform a targeted repair during a low-demand period.

The cost of the SFRA test is minuscule compared to the cost of the failure it prevented. By enabling a shift from reactive, time-based maintenance to proactive, condition-based maintenance, Sweep Frequency Response Analyzers allow for a more efficient allocation of resources, extend the life of valuable assets, and significantly enhance the reliability of the entire power grid. For any organization responsible for high-voltage infrastructure, the question is not whether they can afford to implement SFRA testing, but whether they can afford not to.

Frequently Asked Questions (FAQ)

1. How often should I perform an SFRA test on a transformer? A baseline test should be performed when the transformer is new or after any major repair or relocation. For transformers in critical service or in areas with high fault activity, a routine test every 3-5 years is a good practice. An SFRA test is also highly recommended after a significant external event, such as a major short circuit, a nearby lightning strike, or a seismic event, to check for internal damage.

2. Can I use the SFRA trace from a similar transformer as a baseline? Yes, this is known as a "sister unit" comparison. If you have two or more transformers of the exact same design and from the same manufacturer, the trace from one known healthy unit can be used as a reference for the others. While not as ideal as a true historical baseline for the specific unit, it is a very effective method for identifying deviations, especially when no baseline exists.

3. My SFRA test shows a deviation. Does it mean the transformer will fail tomorrow? Not necessarily. A deviation is an indicator of a physical change, but it does not, by itself, predict the time to failure. The severity of the deviation, the frequency range it occurs in, and the trend over time are all important. A minor deviation may only warrant more frequent monitoring, while a major deviation, especially when confirmed by other tests like DGA, may require immediate action. SFRA is a diagnostic tool, not a prognostic one.

4. What is the main difference between an open-circuit test and a short-circuit test in SFRA? The primary difference is the influence of the magnetic core. In an open-circuit test, the core is part of the magnetic circuit, so the measurement is sensitive to core issues and main inductance. In a short-circuit test, the secondary winding is shorted, which effectively "removes" the core's influence from the measurement. This makes the short-circuit test highly sensitive to winding geometry and leakage inductance, making it the preferred test for detecting winding deformation.

5. Is the SFRA test dangerous or can it damage the transformer? The SFRA test is considered a very safe, non-invasive diagnostic method. The test is performed on a fully de-energized and isolated transformer. The voltage applied by the analyzer is very low (typically 10 volts or less), and the energy involved is minimal. There is no risk of the test itself causing any damage to the transformer's insulation or windings.

6. Does the oil temperature affect the SFRA measurement? Temperature can have a minor effect on the SFRA trace, primarily due to changes in the insulation's properties and slight physical expansion or contraction. However, these effects are generally small compared to the changes caused by a significant mechanical fault. For the most accurate comparison, it is good practice to perform routine tests at a similar transformer temperature, but small temperature differences will not invalidate the test results for detecting major faults.

7. Why is a short, flat grounding braid so important for SFRA testing? A standard long, round wire has a relatively high self-inductance. At the high frequencies used in SFRA testing (up to 2 MHz), this inductance becomes significant and acts as a choke, impeding the proper return path for the signal. This corrupts the measurement, especially in the high-frequency range. A short, wide, flat braid has very low inductance, providing a clean, low-impedance path to ground and ensuring the integrity of the measurement across the entire frequency spectrum.

Conclusion

The internal world of a power transformer is a place of immense forces and delicate geometry. Maintaining the stability of that internal structure is the foundation of ensuring long-term reliability. Sweep Frequency Response Analysis provides a unique and powerful lens into that world. It moves beyond simple pass/fail metrics to offer a rich, detailed portrait of the transformer's mechanical and electrical condition. By establishing a fingerprint and watching for changes, engineers and asset managers can detect the subtle onset of winding deformation, core issues, or faulty connections long before they escalate.

This proactive capability transforms maintenance from a reactive guessing game into a precise, condition-based science. In regions where grid stability is a constant challenge and capital resources are precious, the ability of Sweep Frequency Response Analyzers to prevent catastrophic failures, optimize maintenance spending, and extend the operational life of critical assets is not just an engineering benefit—it is an economic necessity. Embracing this technology is a direct investment in a more reliable, resilient, and secure energy future.