A Practical Guide to Sweep Frequency Response Analysis: 5 Steps to Detect Transformer Faults Early

กันยายน 11, 2025

Abstract

Sweep Frequency Response Analysis (SFRA) is a non-invasive diagnostic method used to assess the mechanical integrity of power transformers. By injecting a low-voltage sinusoidal signal across a wide frequency spectrum and measuring the response, this technique generates a unique frequency-dependent signature for the transformer's active part, including its windings and core. This signature serves as a baseline or "fingerprint." Subsequent tests can be compared to this baseline to detect subtle internal changes. Deviations in the frequency response curve indicate potential mechanical faults such as winding deformation, core displacement, shorted turns, or faulty connections, which may result from transportation stresses, short-circuit events, or aging. The analysis provides a detailed internal view without the need for costly and time-consuming detanking. As a sensitive and reliable condition assessment tool, Sweep Frequency Response Analysis enables early fault detection, facilitates condition-based maintenance, and helps prevent catastrophic failures, thereby enhancing power grid reliability and asset management.

Key Takeaways

- Create a baseline SFRA "fingerprint" for new or healthy transformers for future comparisons.

- Perform tests after significant events like transportation or major short circuits.

- Analyze low-frequency ranges for core problems and mid-to-high ranges for winding issues.

- Use Sweep Frequency Response Analysis to detect winding deformation and ensure mechanical integrity.

- Compare traces between phases of the same transformer to identify potential anomalies.

- Document all test conditions and results meticulously for effective trend analysis.

- Combine SFRA data with other diagnostic tests for a comprehensive transformer assessment.

Table of Contents

- A Practical Guide to Sweep Frequency Response Analysis: 5 Steps to Detect Transformer Faults Early

- Step 1: Grasping the Core Principles of Frequency Response

- Step 2: Meticulous Preparation for a Reliable Test

- Step 3: The Art of Executing the SFRA Measurement

- Step 4: The Interpretive Dance of Analyzing SFRA Traces

- Step 5: From Data to Decision: Documentation and Action

- Frequently Asked Questions (FAQ)

- Conclusion

- References

A Practical Guide to Sweep Frequency Response Analysis: 5 Steps to Detect Transformer Faults Early

A power transformer does not often announce its internal struggles. It stands as a silent, steadfast component of the electrical grid, performing the vital function of voltage conversion. Yet, within its steel tank, it is a complex mechanical structure susceptible to the immense forces of short circuits, the vibrations of transport, and the slow degradation of time. A change in the precise geometry of its windings or a shift in its core can be the quiet precursor to a catastrophic failure, leading to widespread power outages and significant financial loss. How, then, can we listen to the transformer's silent story and understand its internal state of health? This is where the profound diagnostic capability of Sweep Frequency Response Analysis (SFRA) comes into play.

Imagine a finely crafted musical instrument. Its unique sound is a product of its specific physical construction—the tension of its strings, the shape of its body, the density of its wood. If the instrument is dropped or damaged, its sound will change, even if the damage is not visible. The SFRA test operates on a similar principle. It treats the transformer as a complex electrical network of resistors (R), inductors (L), and capacitors (C). By sending a signal through it across a wide range of frequencies, we can map its unique "electrical sound" or signature. Any mechanical change, such as a winding moving by a few millimeters, will alter the inductances and capacitances within, thus changing that signature. This makes Sweep Frequency Response Analysis a powerful tool for peering inside the transformer without ever having to open it. It is a method that moves us from reactive repairs to proactive, intelligent asset management.

Step 1: Grasping the Core Principles of Frequency Response

Before one can effectively use a tool, one must understand the principles upon which it operates. At its heart, a transformer is not just two coils of wire around an iron core; it is an intricate assembly of conductors and insulation. This assembly creates a complex network of resistances, self and mutual inductances, and capacitances between windings, between windings and the core, and between different turns of the same winding.

This RLC network has a unique transfer function, meaning its response to an electrical signal changes depending on the frequency of that signal. At low frequencies, the transformer's behavior is dominated by the magnetizing inductance of the core and windings. At mid-range frequencies, the interaction between windings (mutual inductance and capacitance) becomes more prominent. At very high frequencies, the response is primarily influenced by the individual winding construction and the capacitance between turns. The Sweep Frequency Response Analysis test methodically sweeps a low-voltage signal from a few Hertz up to several Megahertz through this network and measures the ratio of the output signal to the input signal (both in magnitude and phase) at each frequency point. The result is a graph, a unique plot that is the transformer’s fingerprint.

The Transformer as an RLC Circuit

Think of the transformer's internal structure. The long copper conductors of the windings possess inherent resistance (R) and inductance (L). The insulation material (paper, oil) separating these windings from each other, from the core, and from the tank acts as a dielectric, creating capacitance (C). Therefore, the entire transformer can be modeled as a passive, linear RLC network. The impedance of this network is highly dependent on the frequency (f) of the signal passing through it. The inductive reactance (XL) increases with frequency (XL = 2πfL), while the capacitive reactance (XC) decreases with frequency (XC = 1 / 2πfC). This interplay is what creates the distinctive shape of an SFRA trace, with its series and parallel resonant peaks and valleys. A physical deformation, no matter how small, will alter the distances between components, thereby changing the capacitance and inductance, and visibly shifting these resonant points on the graph.

The "Fingerprint" Concept

The foundational idea of Sweep Frequency Response Analysis is comparison. A single SFRA measurement in isolation provides limited information. Its true diagnostic power is unlocked when compared against a reference trace. This reference can be:

- A Factory Baseline: The test performed by the manufacturer before the transformer leaves the factory. This represents the unit in its ideal, as-designed condition.

- A Commissioning Baseline: The test performed on-site after installation but before energization. This accounts for any minor changes that may have occurred during transportation and installation.

- Previous Maintenance Records: Traces from earlier routine tests, which allow for trend analysis to track gradual degradation over time.

- Sister Unit Comparison: A trace from an identical transformer (same design and manufacturer).

- Phase-to-Phase Comparison: Comparing the traces of the three different phases (A, B, C) of the same transformer. Since the phases are typically symmetrical, their traces should be very similar.

A deviation between the current measurement and the reference fingerprint is a clear indication that a physical change has occurred inside the transformer. The nature and frequency range of this deviation provide clues to the type and location of the fault.

SFRA vs. Other Diagnostic Methods

While many diagnostic tests exist for transformers, SFRA is unique in its direct sensitivity to mechanical configuration. Other tests provide information about different aspects of the transformer's health. A holistic assessment often involves combining insights from multiple techniques.

| Diagnostic Method | Primary Purpose | Information Provided | Limitations |

|---|---|---|---|

| Sweep Frequency Response Analysis (SFRA) | Assesses mechanical integrity of the core, windings, and clamping structures. | Detects winding deformation, core movement, shorted turns, and connection issues. | Does not directly measure insulation quality or oil condition. |

| Winding Resistance Measurement | Checks for issues in electrical connections and conductors. | Identifies loose connections, broken conductors, and problems with tap changers. | Insensitive to winding deformation or core problems. |

| Turns Ratio Test (TTR) | Verifies the voltage ratio and detects shorted turns. | Confirms the correct number of turns in each winding. | Can miss subtle mechanical shifts or single-turn shorts. |

| Dissolved Gas Analysis (DGA) | Analyzes gases in the oil to detect thermal and electrical faults. | Indicates overheating, arcing, or partial discharge. | Does not pinpoint the mechanical location of the fault. |

As the table illustrates, Sweep Frequency Response Analysis is not a replacement for other tests but a powerful complement. It provides a unique window into the mechanical soul of the transformer, which other methods cannot offer. Companies like SKF have long championed the principles of condition monitoring in mechanical systems, and SFRA extends this philosophy to the static yet mechanically vulnerable world of transformers.

Step 2: Meticulous Preparation for a Reliable Test

The quality of a Sweep Frequency Response Analysis result is directly proportional to the quality of the preparation. A hastily prepared test can yield misleading data, potentially masking a real problem or, conversely, suggesting a fault where none exists. The process demands a methodical and careful approach, treating the setup with the same gravity as the analysis itself.

Safety First: De-energization and Isolation

Before any connections are made, the transformer must be completely de-energized, isolated from the power system, and locked out according to established safety protocols. Both the high-voltage (HV) and low-voltage (LV) terminals must be disconnected from all external busbars and cables. This is non-negotiable. The presence of external connections would drastically alter the RLC network being measured, rendering the test results meaningless. Furthermore, the transformer tank and core must be securely grounded at a single point to provide a stable reference potential for the measurements. Proper grounding is critical for reducing noise and ensuring repeatable results.

The Importance of the Test Environment

The surrounding environment can influence the measurement. Ideally, the transformer bushings should be clean and dry, as contamination or moisture can create alternative capacitive paths to ground, affecting the high-frequency portion of the trace. It is also important to ensure that the test leads are routed consistently for every test. They should be kept as short as possible, separated from each other, and away from large grounded objects. The braiding of the coaxial test cables provides shielding from external electromagnetic interference, but good practice in lead routing minimizes any residual noise pickup. Recording the ambient temperature and humidity is also good practice, as significant changes in temperature can cause minor, predictable shifts in the response.

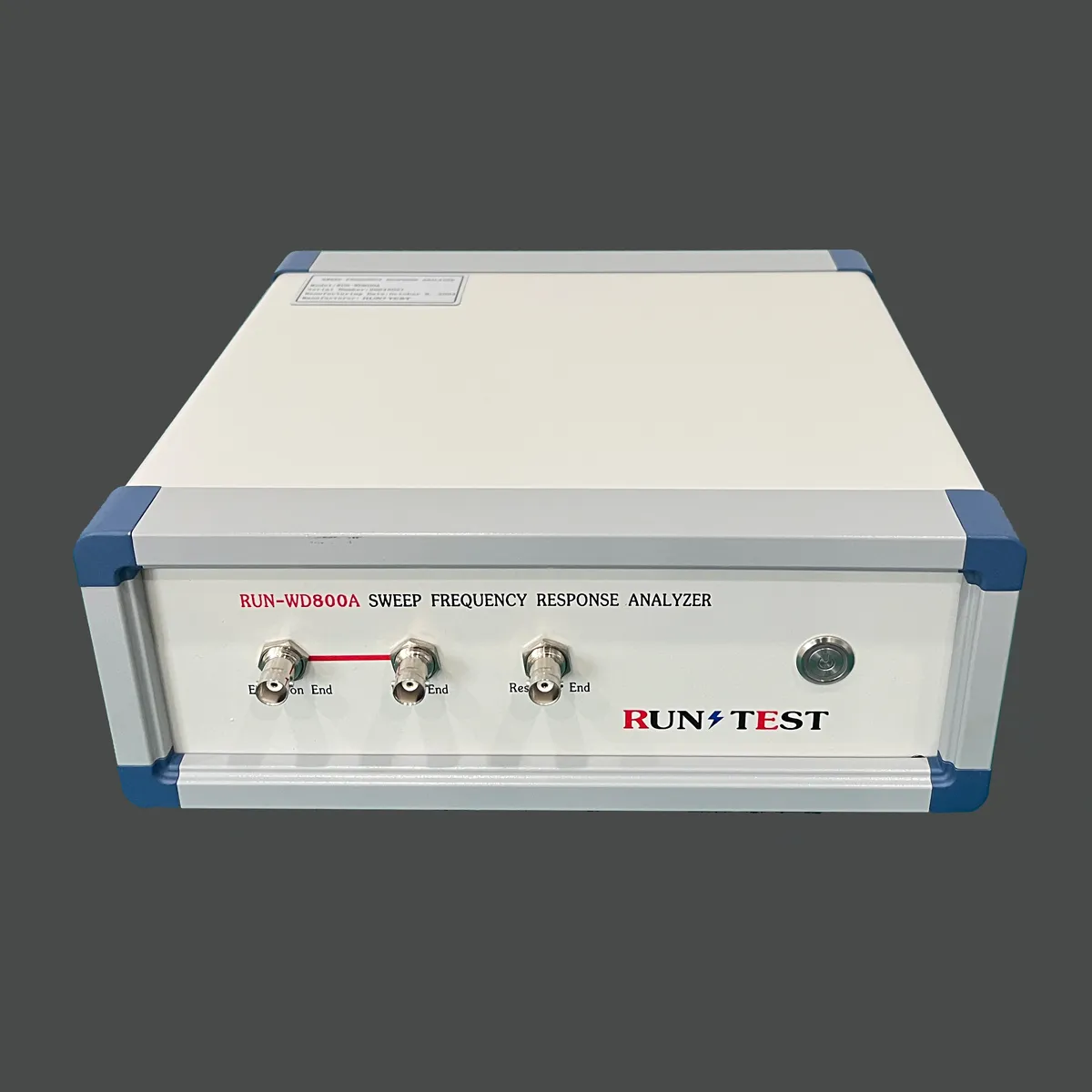

Selecting the Right Test Connections

An SFRA test is not a single measurement but a series of measurements performed with different connection configurations. Each configuration stresses different parts of the transformer's internal RLC network, allowing for a more complete diagnostic picture. The specific tests to be performed are typically defined by standards like IEC 60076-18 and IEEE C57.149. The choice of connections depends on the winding configuration (e.g., delta or wye) and the information being sought. It is crucial to use high-quality transformer test equipment that can perform these varied tests accurately and repeatably. The instrument's software should guide the user through the correct connection sequences for the specific transformer type.

Step 3: The Art of Executing the SFRA Measurement

With the transformer prepared and the test plan in mind, the execution phase begins. This is where the theoretical principles are put into practice. The process involves connecting the SFRA instrument to the transformer bushings according to a predefined sequence and acquiring the data for each test.

Connecting the Instrument

A typical SFRA instrument has two source leads (for injecting the signal) and two measurement leads (for sensing the response). These are connected to the transformer terminals using specially designed clamps that ensure a low-impedance, high-quality connection. For example, in an "end-to-end open-circuit" test on a Y-connected winding, the source might be connected to the H1 bushing and the response measured at the H2 bushing, while H3 and the neutral are left open. The instrument then sweeps the frequency, and the resulting gain/phase plot is recorded. This process is repeated for all three phases and for several different connection types.

Common Test Configurations and Their Purpose

The selection of test configurations is vital for a thorough investigation. Each one provides a unique perspective on the transformer's internal condition. The table below outlines some of the most common tests for a standard YNyn0 transformer.

| Test Name | Connection (Source -> Measurement) | Primary Diagnostic Sensitivity |

|---|---|---|

| HV Open-Circuit Test | H1 -> H1 (with x1, x2, x3 open) | Probes the condition of the main HV winding, sensitive to winding deformation and inter-turn faults. |

| LV Open-Circuit Test | x1 -> x1 (with H1, H2, H3 open) | Probes the condition of the main LV winding. Similar sensitivity as the HV test, but for the LV winding. |

| Inter-Winding Capacitive Test | H1 -> x1 (with all other terminals open) | Measures the capacitance between the HV and LV windings. Highly sensitive to relative movement between windings. |

| HV Short-Circuit Test | H1 -> H1 (with x1, x2, x3 shorted together) | Probes the leakage inductance of the transformer. Very sensitive to winding deformation from high fault currents. |

| Tertiary Winding Tests | (If applicable) | Tests performed on the tertiary winding, following similar principles to the HV and LV tests. |

The instrument's software typically manages this sequence, prompting the operator for the correct connections for each measurement. It is imperative to perform the exact same set of tests each time to ensure the results are comparable to the baseline or previous data. Any deviation in the test procedure will introduce variables that compromise the integrity of the comparison.

Data Acquisition

Once connected for a specific test, the instrument performs the frequency sweep. This might take a few minutes per measurement. The instrument generates a graph of magnitude (in decibels, dB) versus frequency (on a logarithmic scale). A second graph of phase versus frequency is also generated. Modern test sets, such as those found among a wide range of electrical test equipment, save these traces along with all relevant test parameters: transformer details, date, time, temperature, and the specific connection used. This meticulous data logging is the foundation for the analysis that follows.

Step 4: The Interpretive Dance of Analyzing SFRA Traces

This is where science meets experience. Interpreting an SFRA trace is not always a straightforward matter of "good" or "bad." It requires a trained eye, a solid understanding of transformer theory, and a methodical approach to comparison. The goal is to identify significant deviations from the reference trace and correlate them to specific physical phenomena within the transformer.

The Three Key Frequency Regions

The analysis of an SFRA plot is typically broken down into three broad frequency bands, each dominated by different physical characteristics of the transformer.

-

Low-Frequency Region (approx. 20 Hz to 2 kHz): This region is dominated by the bulk inductance of the core and windings. Problems related to the magnetic core, such as shorted laminations, open-circuit conditions in the winding, or major core deformation, will manifest as significant deviations in this band. A loss of core magnetization, for example, would cause a noticeable shift in the entire low-frequency response.

-

Mid-Frequency Region (approx. 2 kHz to 200 kHz): This band is primarily influenced by the magnetic interaction between windings—the leakage inductance and inter-winding capacitance. It is the most sensitive region for detecting bulk winding movements and deformations. A short-circuit event that causes one winding to shift relative to another, or axial/radial buckling of a winding, will produce very clear and dramatic changes here, often shifting the resonant peaks.

-

High-Frequency Region (approx. 200 kHz to 2 MHz): The response in this region is governed by the individual winding's construction, including its internal capacitances and the capacitance of the bushings and leads. This band is sensitive to more localized problems like turn-to-turn shorts, movement of individual conductors, and issues with the tap changer connections. Changes here are often more subtle but can indicate the early stages of a winding fault.

A Case Study in Interpretation

Consider a scenario: A 100 MVA transformer undergoes a Sweep Frequency Response Analysis test as part of routine maintenance. The resulting trace for the HV winding of Phase A is compared to the baseline trace taken two years prior. The analyst observes the following:

- The low-frequency region (below 2 kHz) shows perfect alignment with the baseline. This suggests the core and its magnetization are likely healthy.

- In the mid-frequency region, from 10 kHz to 80 kHz, a significant deviation is noted. The main resonant peak has shifted to a lower frequency, and its amplitude has decreased. This is a classic symptom of increased winding inductance, likely caused by radial deformation or "hoop stress" failure, where the winding has been forced outward, increasing its diameter. This type of damage is a common consequence of an external short-circuit event.

- The high-frequency region (above 200 kHz) shows minor, inconsistent deviations. This might be attributed to slight differences in test lead placement or other noise, but given the major deviation in the mid-band, the focus of the investigation remains on the bulk winding deformation.

Based on this SFRA interpretation, the asset manager can make an informed decision. The result strongly indicates mechanical damage. The next steps might include cross-referencing with DGA results to look for signs of overheating associated with conductor movement and possibly scheduling an internal inspection to confirm the diagnosis before the fault escalates.

The Role of Standards in Interpretation

To standardize the interpretation process, industry bodies have developed guidelines. The IEEE C57.149 standard, for instance, provides a framework for classifying deviations into different categories based on the frequency band and the nature of the change. It also offers numerous case studies that help analysts correlate specific trace patterns with known fault types. Similarly, the Chinese standard DL/T 911-2016 provides a widely used set of criteria for assessing the severity of deviations. These standards are invaluable resources that help transform the subjective art of interpretation into a more objective science.

Step 5: From Data to Decision: Documentation and Action

The final step in the Sweep Frequency Response Analysis process is perhaps the most critical from a management perspective. The data and analysis must be translated into clear documentation and actionable decisions. An SFRA report that sits on a shelf is of no value; its purpose is to guide maintenance strategy and protect the asset.

Building a Comprehensive Report

A good SFRA report is more than just a collection of graphs. It is a complete record of the investigation. It should include:

- Transformer Nameplate Data: Full details of the unit under test.

- Test Conditions: Date, time, ambient temperature, humidity, and the specific test equipment used.

- Test Connections: A clear record of all connections made and measurements taken.

- The Traces: Clear plots of all the measurements, overlaid with the relevant reference traces for comparison.

- Analysis and Interpretation: A detailed, written analysis of the findings. This section should describe any observed deviations, correlate them to specific frequency bands, and propose a probable cause (e.g., "Shift in the main resonance at 55 kHz suggests radial deformation of the HV winding").

- Recommendations: Clear, actionable recommendations. This could be "No significant change detected; continue routine monitoring," or "Significant deviation detected, recommend further investigation with DGA and a possible internal inspection," or "Severe deformation indicated; recommend removing the transformer from service for repair."

The Power of Trending

The true power of a diagnostic program like SFRA is realized over time. By maintaining a historical database of all tests for a given transformer, engineers can perform trend analysis. Small, gradual changes that might be dismissed in a single test can become a clear trend when viewed over several years. This could indicate slow mechanical degradation due to operational stresses or aging. Trending allows for the prediction of future failures and the scheduling of maintenance long before a problem becomes critical, embodying the principle of condition-based maintenance.

Making Informed Maintenance Decisions

Ultimately, Sweep Frequency Response Analysis is a decision-making tool. It helps asset managers answer difficult questions: Is this transformer safe to re-energize after a fault? Did the transformer survive transportation to a new site without damage? Is the gradual change we are seeing a sign of normal aging or impending failure? By providing a clear, evidence-based picture of the transformer's internal mechanical condition, SFRA empowers engineers and managers to move beyond guesswork and make data-driven decisions that enhance safety, improve reliability, and optimize the lifecycle cost of these vital grid assets.

Frequently Asked Questions (FAQ)

What is the primary purpose of a Sweep Frequency Response Analysis (SFRA) test?

The primary purpose of a Sweep Frequency Response Analysis test is to assess the mechanical integrity of a power transformer's active parts. It is exceptionally sensitive to physical changes like winding deformation, core displacement, and faulty internal connections, which are often undetectable by other electrical tests.

How often should an SFRA test be performed on a transformer?

A baseline SFRA test should be performed when the transformer is new (at the factory) and upon commissioning. Subsequently, it should be conducted as part of a regular maintenance schedule (e.g., every 3-5 years), and immediately after any significant event, such as a severe external short-circuit, a nearby lightning strike, or relocation of the transformer.

Can SFRA detect electrical faults like an insulation breakdown?

SFRA is not designed to directly measure insulation quality (like a Megger or Hipot test does). However, it can detect the consequences of some electrical faults. For example, a turn-to-turn short will alter the winding's inductance, which will be visible in the high-frequency region of the SFRA trace.

What is the difference between an open-circuit and a short-circuit SFRA test?

In an open-circuit test, the non-tested windings are left open, and the measurement is primarily influenced by the winding's self-inductance and associated capacitances. In a short-circuit test, the terminals of the secondary winding are shorted together. This focuses the measurement on the leakage inductance of the transformer, making the test highly sensitive to deformations that alter the magnetic flux path between windings.

Is SFRA considered a destructive test?

No, Sweep Frequency Response Analysis is a completely non-invasive and non-destructive test. It uses a very low voltage signal (typically 1-10 volts), which poses no stress or risk to the transformer's insulation or any other component.

What do the "peaks and valleys" on an SFRA graph represent?

The peaks and valleys on the SFRA magnitude plot represent series and parallel resonances within the transformer's RLC network. The exact frequency and amplitude of these resonances are determined by the specific inductance and capacitance values of the windings and core structure. A physical change alters these L and C values, causing the resonant points to shift, which is the key diagnostic principle.

Do I need a baseline "fingerprint" to get value from an SFRA test?

While comparing to a baseline is the most powerful use of SFRA, it is not the only one. A phase-to-phase comparison on a three-phase transformer can be very effective, as the three phases are usually mechanically identical and should have nearly identical traces. A significant difference between phases is a strong indicator of a problem in one of them.

Conclusion

The internal world of a power transformer is a place of immense electrical and mechanical forces. Ensuring the stability of this world is fundamental to the reliability of our entire power infrastructure. Sweep Frequency Response Analysis offers a unique and powerful perspective, allowing us to diagnose the mechanical health of these critical assets with remarkable precision and without intrusive measures. By understanding its principles, preparing and executing tests with care, and interpreting the results with knowledge and diligence, we can identify problems at their inception. This capability shifts the paradigm from reactive failure response to proactive condition management. It transforms the transformer from a black box into an asset whose structural story can be read, understood, and acted upon, securing its longevity and the continuous flow of energy it enables.

References

CIGRÉ Working Group A2.26. (2008). Mechanical-condition assessment of transformer windings using frequency response analysis (FRA) (Brochure 342). CIGRÉ. https://e-cigre.org/publication/342-mechanical-condition-assessment-of-transformer-windings-using-frequency-response-analysis-fra

Dick, E. P., & Erven, C. C. (1978). Transformer diagnostic testing by frequency response analysis. IEEE Transactions on Power Apparatus and Systems, PAS-97(6), 2144–2153.

IEEE Power and Energy Society. (2013). IEEE Guide for the Application of Sweep Frequency Response Analysis to Power Transformers (IEEE Std C57.149-2012). IEEE.

Islam, M. S., Toseef, M., Hussain, G. A., & Lehtonen, M. (2021). A review on the transformer fault diagnosis based on frequency response analysis. International Journal of Electrical Power & Energy Systems, 133, 107297.

Mitchell, S. D., & Welsh, J. S. (2010). Practical aspects of sweep frequency response analysis (SFRA) for transformer condition assessment. In 2010 IEEE International Symposium on Electrical Insulation (pp. 1-5). IEEE.

Rybel, T. D., Birlasekaran, S., & Fetherston, F. (2003). A system approach to the detection of winding movement in power transformers using frequency response analysis. IEEE Transactions on Power Delivery, 18(1), 163–169.

Tenbohlen, S., Coenen, S., Djamali, M., Müller, A., Samimi, M. H., & Siegel, M. (2016). A review of possibilities for applying frequency response analysis (FRA) for power transformer diagnostics. IEEE Transactions on Power Delivery, 31(3), 1046–1055. https://doi.org/10.1109/TPWRD.2015.2509192