7 Critical Reasons Your Substation Needs a CT/PT Analyzer in 2025

Agosto 28, 2025

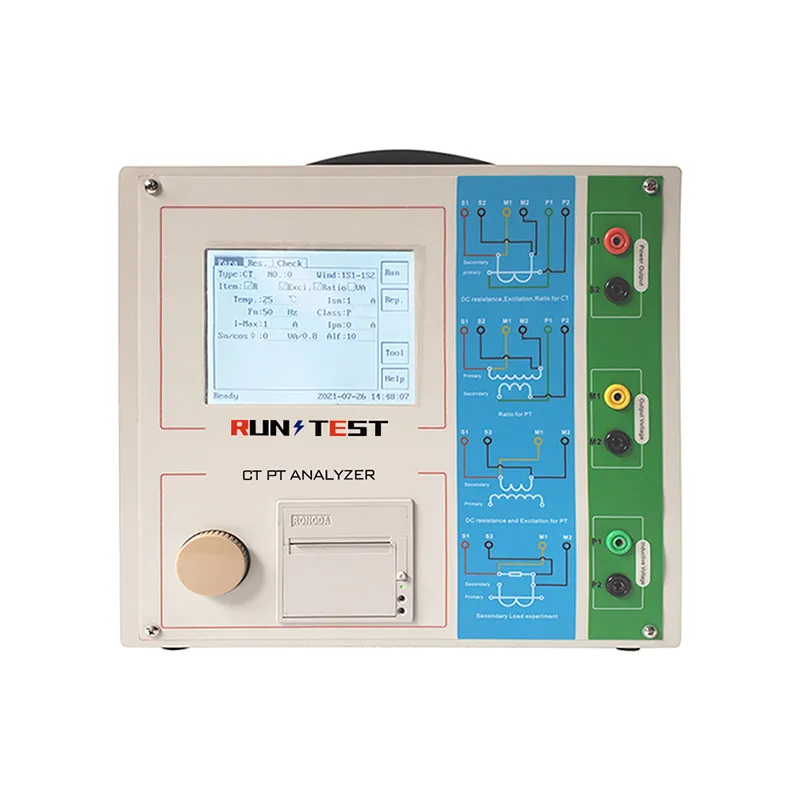

Abstract

Instrument transformers, specifically Current Transformers (CTs) and Potential Transformers (PTs), are foundational components for the protection and monitoring of electrical power systems. The integrity of their performance directly impacts grid stability, equipment safety, and revenue metering. Traditional testing methodologies, often involving multiple separate devices and manual data interpretation, are increasingly viewed as time-consuming, prone to human error, and insufficient for diagnosing the subtle degradation that can precede catastrophic failure. This analysis explores the capabilities of the modern, integrated CT/PT Analyzer as a singular solution to these challenges. By automating a comprehensive suite of tests—including ratio error, phase displacement, excitation curve, winding resistance, and insulation resistance—the CT/PT Analyzer provides unprecedented accuracy and diagnostic depth. This document posits that the adoption of such an analyzer is not merely an operational upgrade but a strategic necessity for enhancing personnel safety, reducing substation commissioning and maintenance times, ensuring compliance with international standards, and implementing a cost-effective, predictive asset management strategy for the year 2025 and beyond.

Key Takeaways

* A modern CT/PT Analyzer combines multiple tests into one automated sequence. * Dramatically reduce on-site testing time compared to traditional methods. * Improve safety by using lower test voltages and automated connections. * Achieve higher accuracy for both protection and metering class transformers. * Simplify compliance reporting with automatically generated digital records. * Enable predictive maintenance by detecting subtle degradation over time. * Gain comprehensive diagnostic insights beyond simple pass or fail results.

Table of Contents

* A Paradigm Shift in Instrument Transformer Testing * Reason 1: Unprecedented Accuracy and Reliability in Measurement * Reason 2: Drastic Reduction in Testing and Commissioning Time * Reason 3: Enhanced Safety for Personnel and Equipment * Reason 4: Comprehensive Diagnostics Beyond Simple Pass/Fail * Reason 5: Simplified Compliance with Evolving International Standards * Reason 6: Versatility for All Types and Classes of Instrument Transformers * Reason 7: Substantial Long-Term Cost Savings and Improved Asset Management * Frequently Asked Questions (FAQ) * Conclusion * References

A Paradigm Shift in Instrument Transformer Testing

Imagine standing within the hum and buzz of a high-voltage substation. All around you is the physical embodiment of immense power. Your responsibility is to ensure that this power is controlled, measured, and directed safely and reliably. In this complex network, some of the most vital yet unassuming components are the instrument transformers. Think of them as the nervous system of the grid. The Current Transformer (CT) and the Potential Transformer (PT, also known as a Voltage Transformer or VT) are translators. They take the impossibly high currents and voltages flowing through the primary lines and step them down to safe, measurable levels that protection relays and meters can understand. Without their accurate translation, a protection relay is blind, and a revenue meter is a liar.

For decades, testing these critical assets has been a laborious affair. An engineer would arrive on-site with a caravan of equipment: a separate winding resistance meter, an insulation tester, a variable AC voltage source, multiple multimeters, and a tangle of cables. Each test—ratio, polarity, excitation, resistance, insulation—was a separate, manual procedure requiring different connections, careful calculations, and meticulous handwritten records. The entire process was slow, susceptible to connection errors, and posed significant safety risks, particularly when dealing with the dangers of an accidentally opened CT secondary circuit.

This methodology, while functional for its time, no longer meets the demands of the modern grid. Today’s power systems are more dynamic, the protection schemes more sophisticated, and the economic penalties for outages or mis-metering more severe. We need a testing philosophy that is faster, safer, and offers deeper insight. This is the intellectual space occupied by the modern CT/PT Analyzer. It represents a fundamental shift from a piecemeal approach to an integrated, intelligent diagnostic system. It is not just another tool; it is a new way of thinking about asset health.

The table below offers a clear comparison, contrasting the burdens of the past with the efficiencies of the present.

| Feature | Traditional Testing Method | Modern CT/PT Analyzer | | :— | :— | :— | | Equipment Required | Multiple separate instruments (5+) | One single, portable unit | | Testing Time per CT | 2-4 hours | 15-30 minutes | | Connection Changes | Required for each individual test | One-time connection for all tests | | Safety Risks | High (open-circuit CT, high voltages) | Low (automated, low-voltage testing) | | Data Analysis | Manual calculation, plotting, and interpretation | Automated analysis and comparison to standards | | Reporting | Manual data entry, prone to transcription errors | Automatic generation of digital, tamper-proof reports | | Diagnostic Capability | Basic pass/fail | In-depth diagnostics, trend analysis |

This evolution from a collection of single-function tools to a comprehensive diagnostic platform is where the true value lies. The conversation is no longer just about whether a CT “works.” It is about understanding its precise condition, predicting its future performance, and managing its lifecycle with intelligence and foresight.

Reason 1: Unprecedented Accuracy and Reliability in Measurement

At the heart of any measurement or protection system lies a simple question of trust. Can we trust the values our instruments are reporting? When a protection relay sees a fault current of 2000 amps, is it truly 2000 amps on the primary line, or is it 1900 amps, or 2100? This difference, which may seem small, can be the margin between a correctly timed trip that isolates a fault and a delayed operation that results in catastrophic equipment damage. The accuracy of the instrument transformer is not an academic detail; it is the bedrock upon which the entire protection philosophy is built. A modern CT/PT Analyzer is engineered to interrogate this accuracy with a level of precision that traditional methods struggle to match.

The Fallacy of “Good Enough” in Protection Systems

There can be a tendency to think of protection-class CTs as less demanding of accuracy than their metering-class counterparts. After all, their primary job is to operate under massive fault conditions, not to bill a customer for kilowatt-hours. This line of reasoning contains a perilous oversimplification. While the accuracy class for protection CTs (e.g., C400 in the US, 5P10 in an IEC context) allows for a larger error margin at nominal currents, their performance during a fault is what truly matters. It is during these high-current events that a CT can saturate. Saturation occurs when the magnetic core of the CT can no longer handle the immense magnetic flux generated by the primary current. When a CT saturates, its secondary output no longer accurately reflects the primary current. It essentially lies to the relay, reporting a lower fault current than what is actually occurring. This can cause a severe delay in the tripping of a circuit breaker, allowing destructive energy to flow for far longer than designed. A CT/PT Analyzer directly assesses the saturation characteristics, ensuring the CT will perform when it is needed most.

How a CT/PT Analyzer Measures Ratio and Phase Angle Error

Every instrument transformer has a nameplate ratio, such as 400:5. This suggests that for every 400 amps flowing in the primary, 5 amps will flow in the secondary. In reality, no transformer is perfect. There will always be a small ratio error (the difference between the actual and nameplate ratio) and a phase angle error (a slight time shift between the primary and secondary signals). For metering CTs, these errors directly translate into lost or gained revenue. For protection CTs, particularly in differential protection schemes, a mismatch in phase angles between two sets of CTs can be misinterpreted by the relay as an internal fault, causing a nuisance trip of a perfectly healthy transformer or generator.

A CT/PT Analyzer does not just check the ratio at one or two points. It injects a variable voltage/current and precisely measures the resulting output across a range of operating points. It models the transformer’s behavior and calculates the ratio and phase angle errors with laboratory-grade precision, often down to 0.02% and 1 minute of arc. It can perform these measurements at different burdens, simulating the real-world load placed on the CT by the connected relays and wiring. This provides a complete and nuanced picture of the transformer’s accuracy, one that is impossible to achieve with a simple load box and a pair of ammeters.

Excitation Curve Analysis: The True Fingerprint of a CT

If a CT has a fingerprint, it is its excitation curve (or saturation curve). This curve plots the relationship between the voltage applied to the secondary winding and the resulting excitation current that flows. It reveals everything about the health of the CT’s magnetic core. To perform this test traditionally, a technician would need a large, heavy, and manually operated variable AC voltage source (a Variac). They would have to slowly increase the voltage while carefully recording pairs of voltage and current readings, paying close attention as the current begins to increase dramatically. This point of sharp increase is known as the “knee point,” and it defines the limit of the CT’s accurate operating range. This manual process is not only time-consuming but also dangerous, as it often requires applying several hundred or even a few thousand volts to the secondary terminals.

A CT/PT Analyzer revolutionizes this critical test. Using advanced modeling techniques, it performs the entire test using a low test voltage, typically below 180V. It injects a signal, measures the response, and then mathematically constructs the full excitation curve up to 30,000V. It automatically identifies the knee point voltage according to all relevant IEEE and IEC standards. The analyzer can then overlay this measured curve with the one from a previous test or a “golden” curve from the manufacturer. Any deviation—a lower knee point, for example—can indicate issues like shorted turns in the winding or a damaged core, providing a clear and early warning of degradation long before it would be apparent in a simple ratio test.

Reason 2: Drastic Reduction in Testing and Commissioning Time

In the world of substation operations, time is a resource as valuable as electricity itself. Whether commissioning new equipment or performing periodic maintenance, every hour the system is de-energized or a crew is on-site represents significant cost and operational disruption. The traditional approach to instrument transformer testing is notoriously time-intensive, a relic of an era when labor was less expensive and outage windows were more generous. The adoption of a modern CT/PT Analyzer is perhaps most immediately felt in the dramatic compression of on-site testing schedules. This efficiency gain is not incremental; it is transformative.

The Old Way: A Marathon of Multiple Devices and Manual Calculations

Let us paint a picture of the conventional testing process for a single, three-phase set of current transformers on a circuit breaker. First, the technician must isolate the equipment and ensure it is safe to approach. Then, the testing marathon begins.

1. Winding Resistance: Connect a specialized micro-ohmmeter to the secondary terminals. Take the reading, record it. Disconnect. 2. Insulation Resistance: Connect a megohmmeter between the windings and ground. Perform the test for one minute. Record the reading. Disconnect. 3. Ratio/Polarity: Connect a high-current injection source to the primary side and an ammeter to the secondary. This often requires heavy cables and a significant power source. Inject current, take readings, and verify polarity. Disconnect. 4. Excitation: Connect the large, heavy Variac to the secondary. Manually ramp up the voltage, carefully noting down dozens of voltage and current data points. Plot these points by hand or in a spreadsheet to find the knee point. This is the most time-consuming and hazardous part of the process.

Each step involves a different piece of equipment, a different connection setup, and its own potential for error. For a single CT with one core, this can easily take two hours. For a CT with multiple cores (e.g., for differential, overcurrent, and metering), the time multiplies. Commissioning a new bay with a dozen such CTs could consume days of work for a skilled crew.

The New Way: A Single Connection for a Full Suite of Tests

Now, consider the workflow with a state-of-the-art CT/PT analyzer. The technician makes one single set of connections to the secondary terminals of the CT (and a connection to the primary side, if needed for ratio). From the analyzer’s user interface, they select the desired test plan. With the press of a single button, the instrument executes the entire suite of tests automatically:

* Winding resistance * Insulation resistance (often integrated or with a simple accessory) * Ratio and phase angle error across multiple points * Excitation curve and knee point calculation * Burden measurement * Inductance and other diagnostic parameters

The entire sequence for a single core is completed in minutes, not hours. There is no heavy equipment to haul, no manual plotting of curves, and no constant reconnecting of leads, which is a major source of mistakes. The results are displayed instantly and saved to internal memory with a timestamp, asset ID, and temperature reading for a complete, traceable record.

The time savings are profound, as illustrated in the table below.

| Test Parameter | Traditional Method Time | CT/PT Analyzer Time | Time Savings | | :— | :— | :— | :— | | Winding Resistance | 15 minutes | < 1 minute | > 90% | | Insulation Resistance | 10 minutes | < 2 minutes | 80% | | Excitation Curve | 45-60 minutes | < 2 minutes | > 95% | | Ratio & Phase Angle | 30 minutes | < 5 minutes | > 80% | | Total (per core) | ~100-120 minutes | ~10 minutes | ~90% |

A Case Study: Commissioning a New Substation Feeder

Consider a real-world scenario in a growing urban center in Southeast Asia, where a utility is adding a new 132 kV feeder to cope with increasing demand. This project involves twelve bushing CTs, each with three cores (one for metering, one for main protection, one for backup protection), for a total of 36 cores to be tested.

With the traditional method, a two-person crew would budget at least 1.5 hours per core. That’s 36 cores * 1.5 hours/core = 54 man-hours, or nearly three full days of dedicated testing time, not including setup, safety briefings, and report generation.

Using a modern CT/PT Analyzer, the same crew can complete a full test on a core in about 15 minutes, including moving between bushings. The total testing time becomes 36 cores * 0.25 hours/core = 9 man-hours. The entire commissioning test for all instrument transformers can be completed in a single day. This frees up the skilled crew for other tasks, shortens the overall project timeline, and allows the new feeder to be energized and start generating revenue much sooner. This is not just a marginal improvement; it is a fundamental change in project economics and resource allocation.

Reason 3: Enhanced Safety for Personnel and Equipment

In the high-voltage environment of a substation, safety is not merely a policy; it is a prerequisite for survival. Every procedure, every tool, and every action must be evaluated through the lens of risk mitigation. Traditional instrument transformer testing methods, while established, carry inherent risks that have been accepted as a “cost of doing business” for too long. A core design principle of the modern CT/PT Analyzer is the systematic reduction of these risks, creating a safer working environment for the technicians who are the lifeblood of our power grids. This focus on safety protects not only people but also the expensive equipment they are testing.

Mitigating the Dangers of an Open CT Secondary

Every electrical apprentice learns the cardinal rule of current transformers: never, ever open-circuit the secondary winding while the primary is energized. A CT works by stepping down current, which means it steps up voltage. If the primary circuit is carrying its load and the secondary circuit is opened, the CT will attempt to drive its secondary current into an infinite impedance. This induces an extremely high, potentially lethal voltage across the open terminals—many thousands of volts. This can cause a dangerous arc flash, permanently damage the CT’s insulation, and poses a severe electrocution hazard to anyone nearby.

Traditional testing methods, with their constant connecting and disconnecting of various instruments, create multiple opportunities for this hazardous condition to occur accidentally. A lead could slip, a connection could be forgotten, or a simple human error could have dire consequences. The CT/PT Analyzer mitigates this risk at its source. With its one-time connection philosophy, the secondary circuit is connected to the low-impedance input of the analyzer at the beginning of the test sequence and remains so until all tests are complete. Furthermore, many analyzers have built-in secondary voltage monitoring that will automatically shut down the test and alert the operator if an unsafe voltage is detected, providing an active layer of protection.

Lower Test Voltages, Higher Safety Standards

The classic excitation curve test is a prime example of high-risk procedures. As mentioned, it requires the technician to manually apply a high AC voltage to the secondary terminals, often reaching several hundred or even over 1000 volts to find the saturation knee point. This involves working with a powerful, manually controlled voltage source that can deliver a fatal shock.

The CT/PT Analyzer completely eliminates this specific hazard. It uses a sophisticated, low-voltage injection method. By sending a controlled signal and precisely measuring the response, it uses advanced algorithms to model the CT’s magnetic characteristics and calculate the knee point voltage without ever having to generate it directly. The maximum voltage produced by the analyzer during this test is typically less than 180V, and often much lower, which is significantly safer to work with. This removes one of the most dangerous tasks from the field technician’s routine, a significant step forward in occupational safety recognized by leading industrial technology firms like [SKF](https://www.skf-eu.com/about-us/).

Automated Procedures Reduce Human Error

Fatigue, distraction, and momentary lapses in concentration are part of the human condition. In a substation environment, these can lead to errors like connecting an instrument to the wrong terminals, misinterpreting a reading, or failing to follow a procedure in the correct sequence. Automation is the most powerful tool we have to combat the influence of human fallibility.

A CT/PT Analyzer automates the entire testing workflow. The operator selects the asset to be tested and the desired test plan. The instrument then takes over, executing each test in the correct order, applying the correct signals, and recording the results without manual intervention. It can even detect common wiring mistakes, such as reversed polarity, and alert the user before proceeding. By turning a complex, multi-step manual task into a guided, automated process, the analyzer not only speeds up the work but also builds in layers of safety checks. This reduction in the “human factor” is a cornerstone of modern safety engineering, ensuring that tests are performed consistently and safely, every single time, regardless of who is operating the device.

Reason 4: Comprehensive Diagnostics Beyond Simple Pass/Fail

An instrument transformer can be thought of like a human heart. A simple check might confirm that it’s still beating, but this tells you very little about its actual health. Is there a blockage in an artery? Is a valve wearing out? To truly understand its condition, you need a more sophisticated diagnostic tool, like an EKG, that can look deeper. Traditional testing methods are often like that simple pulse check; they can give you a basic pass or fail, a “yes, it works” or “no, it doesn’t.” A modern CT/PT Analyzer, in contrast, is the EKG for your instrument transformers. It provides a rich, multi-faceted diagnostic report that reveals not just the current state but also the subtle signs of developing problems.

Winding Resistance: Detecting Internal Faults Early

Measuring the DC resistance of the secondary winding is a fundamental test. A value that is significantly higher than the manufacturer’s specification or a previous reading can indicate problems like a loose internal connection, a corroded terminal, or even a partially broken conductor within the winding. These are faults that might not immediately cause a complete failure but can lead to increased heating, inaccurate readings, and eventual breakdown. A CT/PT Analyzer measures this resistance with high precision using a four-wire Kelvin connection method, which eliminates the resistance of the test leads themselves from the measurement, ensuring a true and repeatable reading. By tracking this value over the transformer’s life, you can spot a rising trend that signals a developing issue long before it becomes critical.

Insulation Resistance: Preventing Catastrophic Failures

The insulation system is arguably the most critical component of any high-voltage apparatus. It is what keeps the high potential where it belongs. The degradation of this insulation—due to moisture, heat, age, or contamination—is a leading cause of failure in instrument transformers. A failure of the primary-to-secondary insulation can be catastrophic, impressing full line voltage onto the low-voltage protection and control wiring, destroying relays, and creating an extremely dangerous situation.

A CT/PT Analyzer or a companion device performs an insulation resistance test (megohmmeter test) by applying a DC voltage (e.g., 500V, 1000V, 2500V) and measuring the resulting leakage current. The calculated resistance value gives a quantitative measure of the insulation’s quality. But the diagnostics go deeper. By performing a Polarization Index (PI) test—a ten-minute test compared to a one-minute reading—the analyzer can assess the condition of the insulation more thoroughly. A healthy, dry insulation system will show a steadily increasing resistance over the test period, resulting in a PI value greater than 2. A low or flat PI value can indicate moisture ingress or contamination, a clear warning to investigate further or schedule a replacement.

Burden Measurement: Ensuring the System Works as a Whole

A current transformer does not operate in a vacuum. It is connected to a load, or “burden,” which consists of the protection relays, meters, and the resistance of the connecting wires. The CT is designed to maintain its accuracy only up to a certain maximum burden, specified on its nameplate (e.g., B-0.5, meaning it can handle a load of 0.5 ohms). If the actual connected burden exceeds this value, the CT will be forced to produce a higher voltage to drive the secondary current, which can push it into saturation and cause gross inaccuracies.

It is a common mistake to assume the connected burden matches the design calculations. Wires might be longer than planned, a relay might have been replaced with a different model, or an extra device might have been added to the circuit. A CT/PT Analyzer can directly measure the actual connected burden. It injects a nominal current into the secondary loop (with the primary disconnected, of course) and measures the voltage drop, calculating the precise impedance (in VA or ohms) of the entire loop. This verifies that the CT is operating within its design limits. Finding a burden that is too high is a simple yet powerful diagnostic check that can solve many puzzling protection performance issues. It is this ability to test the component within the context of its system that elevates the analyzer from a simple tester to a true diagnostic tool.

Reason 5: Simplified Compliance with Evolving International Standards

Operating in the global power industry means navigating a complex web of technical standards. These standards, primarily developed by bodies like the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), are not just recommendations; they are the language of international trade, safety, and interoperability. For companies operating across diverse regions like South America, Russia, Southeast Asia, and the Middle East, demonstrating compliance with the relevant standards (e.g., IEC 61869, IEEE C57.13) is essential for project acceptance, regulatory approval, and maintaining a reputation for quality. A modern CT/PT Analyzer is an indispensable ally in this process, transforming compliance from a bureaucratic headache into a streamlined, automated workflow.

Navigating the Complexities of IEC and IEEE/ANSI Standards

The standards governing instrument transformers are dense and highly technical. They define everything from accuracy classes and saturation characteristics to terminal markings and testing procedures. For example, the way the knee point of an excitation curve is defined differs between IEEE C57.13 (the point where a 10% increase in voltage causes a 50% increase in current) and IEC 61869-2 (the voltage at which an increase of 10% results in a 50% increase in excitation current, at a specific excitation current value). Remembering and correctly applying these different definitions during manual testing is a challenge ripe for error.

A CT/PT Analyzer has these standards built directly into its software. When setting up a test, the operator simply selects the relevant standard from a menu. The analyzer then automatically performs the test and evaluates the results according to the precise definitions and limits specified in that standard. For a protection CT, it will automatically classify it (e.g., as C400 or 5P10) based on the measured data. This removes any ambiguity or need for manual interpretation. The result is no longer an engineer’s opinion; it is a direct, objective comparison of the asset’s performance against a globally recognized benchmark.

Automated Reporting for Audits and Record-Keeping

The final product of any testing and commissioning job is the report. This document is the official record that proves the work was done correctly and the equipment meets specification. Traditionally, creating these reports was a tedious, post-job task. It involved manually transcribing pages of handwritten field notes into a spreadsheet or document, plotting curves, and formatting the data. This process was not only time-consuming but also a frequent source of transcription errors. An incorrectly typed number could call the entire test into question during an audit.

Modern CT/PT analyzers completely automate this process. As each test is completed, the results are stored digitally in the device’s memory, linked to the specific asset ID, substation, and feeder information entered by the operator. Once all tests are finished, a comprehensive, professional report can be generated with a single click. This report includes all test parameters, results, pass/fail assessments against the selected standard, and graphical representations of data like the excitation curve. The report can be transferred to a computer via USB or Wi-Fi and is often in a tamper-proof format like PDF. This creates a perfect, traceable, and easily archivable record for asset management systems, client handover packages, and regulatory audits.

Future-Proofing Your Testing Protocol

Standards are not static. As technology evolves and our understanding of asset behavior deepens, standards are periodically reviewed and updated. A testing protocol that relies on manual methods and institutional knowledge can quickly become outdated. Keeping an entire team of field engineers up-to-date with the latest revisions to multiple international standards is a significant training challenge.

Investing in a high-quality CT/PT Analyzer from a reputable manufacturer is a way to future-proof your testing program. These manufacturers are active participants in the standards committees and provide regular firmware updates for their instruments. When a standard is revised, a simple software update can bring the analyzer’s testing algorithms and assessment criteria into alignment with the latest requirements. This ensures that your company’s testing practices remain compliant and reflect the current state of the art in the industry, without the need for extensive retraining of personnel. It is an investment in a testing ecosystem, not just a piece of hardware.

Reason 6: Versatility for All Types and Classes of Instrument Transformers

Substations are not uniform environments. They are a diverse collection of equipment from different eras, from various manufacturers, and designed for a multitude of applications. A testing solution that is only effective on one specific type of instrument transformer is of limited use. The true power of a modern CT/PT Analyzer lies in its remarkable versatility. It is a multi-talented tool, designed with the flexibility to accurately assess the health of a vast range of current and potential transformers found across the grid, from old electromechanical installations to the latest gas-insulated switchgear.

Testing Protection vs. Metering Class CTs

At a glance, a protection CT and a metering CT might look similar, but they are designed for fundamentally different jobs. A metering CT is designed for high accuracy within the normal operating current range of a circuit. Its purpose is to ensure precise billing. A protection CT, conversely, is designed to maintain reasonable accuracy at very high overcurrents so it can reliably inform a relay about a fault condition. It is allowed to be less accurate at normal currents but must not saturate too early during a fault.

These different design philosophies require different testing approaches. A CT/PT Analyzer understands this distinction. For a metering CT, it will focus on performing highly precise ratio and phase angle measurements at multiple points within the nominal current range (e.g., at 5%, 20%, 100%, and 120% of rated current). For a protection CT, while it still measures the ratio, its primary focus will be on accurately determining the excitation curve and the knee point to verify its performance under fault conditions. The analyzer’s software allows the user to specify the application, and it then tailors the test sequence and assessment criteria accordingly, providing the most relevant information for each type.

Handling Complex Transformers: Bushing CTs and GIS Systems

The versatility of the analyzer extends to the physical form of the CT. It can test traditional “donut” or window-type CTs, bar-type CTs, and wound-primary CTs. More importantly, it is perfectly suited for testing CTs that are integrated into other equipment, which are often the most difficult to access.

Bushing Current Transformers (BCTs): These CTs are located inside the main bushings of large power transformers or circuit breakers. They often have multiple taps on the secondary winding to provide different ratios from the same unit. A CT/PT Analyzer can easily test each tap ratio automatically, verifying the entire range of the BCT’s functionality without requiring complex manual reconnection for each tap.

Gas-Insulated Switchgear (GIS): In modern compact substations, CTs and PTs are often housed within the sealed, SF6 gas-filled environment of the switchgear. Access to the primary conductor is impossible. The CT/PT analyzer is ideal for this application because it can perform most of its critical tests (excitation, winding resistance, insulation) by connecting only to the secondary terminals, which are accessible in an external junction box. It can even determine the ratio without primary injection by using a voltage-based method or by injecting a small current into the secondary and measuring the induced voltage on an adjacent winding.

Adapting to Potential Transformers (PTs) and CVTs

As its name suggests, the CT/PT Analyzer is not limited to current transformers. It is a dual-purpose instrument also capable of fully testing Potential Transformers (PTs), also known as Voltage Transformers (VTs). It can accurately measure the ratio and phase error of a PT, check its winding resistance, and perform an excitation test on the magnetic core, just as it does for a CT.

Furthermore, it can handle the more complex Capacitor Voltage Transformers (CVTs). A CVT uses a stack of capacitors as a voltage divider in conjunction with a smaller magnetic transformer. Testing a CVT requires a different approach than a standard inductive PT. A capable CT/PT analyzer has specific test modes for CVTs that can assess the condition of both the capacitor stack and the electromagnetic unit, providing a complete health report for these common and critical high-voltage measurement devices. This ability to test virtually any type of instrument transformer with a single device provides enormous value and simplifies tooling requirements for maintenance teams. You can explore a [comprehensive range of CT/PT analyzers](https://www.voltage-tester.com/ct-pt-analyzer-category/) to see the variety of features available for these diverse applications.

Reason 7: Substantial Long-Term Cost Savings and Improved Asset Management

While the initial purchase of a high-quality CT/PT Analyzer represents a significant capital expenditure, viewing it solely as a cost is a mistake in financial reasoning. A more appropriate framework is to consider it an investment with a clear and substantial return. This return is not realized in a single “profit” event but is accrued over time through increased efficiency, reduced operational costs, avoided failures, and optimized asset lifecycle management. In the financially constrained and reliability-focused world of modern utilities, the economic argument for adopting this technology is as compelling as the technical one.

Calculating the ROI: Beyond the Initial Investment

The return on investment (ROI) for a CT/PT Analyzer is multi-faceted. The most immediate and easily quantifiable return comes from the reduction in labor costs. As demonstrated earlier, a testing sequence that took a two-person crew three days can now be done in one. This is a 67% reduction in direct labor costs for that task. When this saving is multiplied across all the instrument transformers in a utility’s fleet and all the commissioning and maintenance cycles over a year, the savings become enormous. This saved time allows skilled technicians to be reallocated to other valuable work, increasing the overall productivity of the workforce.

Further savings come from reduced outage times. Faster testing means circuits can be returned to service more quickly. For generation or transmission assets, every hour of availability has a direct monetary value. Shortening a maintenance outage on a key transmission line by a full day could represent a saving that is many times the cost of the test equipment itself.

Predictive Maintenance: From Reactive Repairs to Proactive Care

The greatest, though perhaps hardest to quantify, financial benefit comes from the shift from a reactive, time-based maintenance schedule to a proactive, condition-based one. Traditional maintenance often follows the calendar: “We test every CT every five years.” This approach is inefficient. It means a perfectly healthy CT is subjected to a costly test, while a degrading CT might fail in year three, long before its scheduled check-up.

A CT/PT Analyzer enables a true predictive maintenance strategy. By storing and trending the results of key diagnostic tests—such as excitation curve characteristics, winding resistance, and insulation quality—over time, it is possible to see the subtle signs of degradation. An excitation knee point that has dropped by 5% since the last test, or a winding resistance that has increased by 3%, are clear indicators of an aging asset. This data allows maintenance managers to move away from the “run to failure” or “test everything” models. Instead, they can focus their resources precisely where they are needed most, intervening to repair or replace an asset before it fails in service. This proactive approach avoids the immense costs associated with unplanned outages, collateral equipment damage, and potential safety incidents. This philosophy is at the core of what many leading manufacturers of transformer testers advocate for.

Extending the Lifespan of Your Critical Assets

Instrument transformers are long-life assets, but their lifespan is not infinite. By understanding their precise condition, utilities can make more informed decisions about repair, refurbishment, or replacement. Perhaps a set of older CTs, while still functional, is found to have a high burden sensitivity that makes them unsuitable for a new digital relay upgrade. The data from the analyzer provides the objective evidence needed to justify their replacement. Conversely, a set of 25-year-old CTs might be shown to be in pristine condition, allowing the utility to confidently defer the cost of their replacement and invest that capital elsewhere.

By providing a clear, objective, and detailed health report for each asset, the CT/PT Analyzer transforms instrument transformers from unmonitored black boxes into managed assets. This data-driven approach to asset management allows for smarter capital planning, reduced risk of failure, and ultimately, the extension of the useful life of the existing fleet, maximizing the value of every asset in the substation.

Frequently Asked Questions (FAQ)

What is the main difference between a CT analyzer and just using a multimeter and a variable voltage source? The primary difference is integration, automation, and safety. While you can perform some individual tests with separate instruments, a CT/PT Analyzer integrates all tests into one device. It automates the entire sequence, performs calculations automatically, compares results to international standards, and generates a report. Critically, it performs tests like the excitation curve using safe, low-voltage methods, eliminating the need to manually handle hazardous high voltages.

How often should I test my instrument transformers with a CT/PT analyzer? This depends on the asset’s criticality, age, and environment, but a common practice is to perform a full test during commissioning and then again every 3-5 years for maintenance. For highly critical transformers, such as those on large generators or main transmission lines, a shorter interval of 2-3 years might be justified. The key benefit of the analyzer is that the quick, detailed tests allow for more frequent health checks if a problem is suspected.

Can a single analyzer test both CTs and PTs? Yes, most modern instruments marketed as “CT/PT Analyzers” are designed to test both Current Transformers (CTs) and Potential/Voltage Transformers (PTs/VTs), including Capacitor Voltage Transformers (CVTs). They have specific test modes and connection adapters for each type of instrument transformer.

Is it difficult to learn how to use a modern CT/PT analyzer? No. Reputable manufacturers design their analyzers with user-friendly interfaces, often featuring large touch screens and guided test procedures. While a solid understanding of electrical principles is necessary, the device walks the user through the connection process and automates the test execution. A technician familiar with basic substation testing can become proficient with an analyzer after a single day of training.

Does the analyzer work for older, legacy equipment? Absolutely. In fact, this is one of its most valuable applications. Older instrument transformers are more likely to have degraded, and their original factory test reports are often lost. A CT/PT analyzer can create a new, highly accurate baseline “fingerprint” (especially the excitation curve) for this legacy equipment, allowing you to assess its current health and track its condition moving forward.

What is the importance of testing the CT burden? Testing the burden is vital because a CT is only guaranteed to be accurate if the connected load (relays, meters, wires) is within its rated burden value. If the actual burden is higher than the CT’s rating, the CT can saturate during a fault and fail to operate the protection system correctly. The analyzer directly measures the true burden of the connected circuit, confirming the CT is operating within its design limits.

How does a CT/PT analyzer enhance safety during testing? It enhances safety in several key ways. It uses low test voltages (typically <180V) to perform tests that traditionally required hazardous high voltages. Its one-time connection methodology minimizes the risk of accidentally opening a CT secondary circuit. Finally, its automated test sequences reduce the amount of manual intervention required, lowering the chance of human error in a high-voltage environment.

Conclusão

The evolution of technology often presents us with tools that are merely faster or more convenient. The modern CT/PT Analyzer, however, offers something more profound. It represents a fundamental re-evaluation of how we ensure the health and reliability of the nervous system of the power grid. To persist with traditional, fragmented testing methods in 2025 is to willingly accept unnecessary risks, operational inefficiencies, and a dangerously incomplete understanding of our most critical assets.

The adoption of an integrated analyzer is not about replacing old hardware; it is about embracing a new philosophy of precision, safety, and foresight. It empowers engineers and technicians to move beyond simple pass/fail judgments and to engage in a meaningful diagnostic conversation with their equipment. The benefits are clear and compelling: a dramatic reduction in time on-site, a verifiable enhancement in personnel safety, an unimpeachable level of accuracy compliant with global standards, and the establishment of a data-driven, predictive maintenance program that saves money and prevents catastrophic failures. In an era where the stability of our electrical infrastructure is more important than ever, the CT/PT Analyzer is no longer a luxury—it is the standard of care for any serious power system professional.